This 'SAM' term is widely used by industrial engineers and garment production people in the garment manufacturing industry. This article will explain the SAM calculation method for individual sewing operations. To learn it, keep reading.

The SAM plays an important role in estimating the cost of making a garment. In the past, scientists and apparel technicians did research on how much time to be allowed to perform a job when one follows the standard method of doing the job.

According to the research study, the minute value has been defined for each movement needed to accomplish a job. Synthetic data is available for each movement.

General Sewing Data (GSD) has defined a set of codes for motion data for SAM calculation. There are also other methods through which one can calculate the SAM of a garment without using synthetic data or GSD.

Both methods are explained below.

Method 1: Calculate Garment SAM Using Synthetic Data

In this method, the 'Predetermined Time Standard' (PTS) code is used to establish the 'Standard Time' of individual garment operations or other sewn products. A training is necessary for using the motion study of the operations and deriving standard tme of the sewing operations. I have shared the steps that you can follow to learn method applied in SAM calculation using synthetic data.

Step 1: Operation and operator selection

If you are working in a factory, you can perform this study with with live operator. Go to the sewing floor, select one operator from a running sewing line and select the operation for which you need to calculate SAM. You can also choose operation and sewing operator from the sampling room.

Step 2: Study the motions of that operation.

Once you have idenified an operator for motion study, study his movement while sewing a garment operation. Stand by the side of an operator (an experienced one) and observe the operator to understand how he is doing the operation.

Note down all movements used by the operator in doing one complete cycle of work. Observe carefully again and recheck your notes to see whether all movements/motions are captured and correct. For example, motions are like - pick up parts with one hand or two hands, align parts on the table or machine foot, realign plies, etc.)

Draw a line diagram of the workstation to refer it later for your analysis. mark the placement of the parts (garment panels) before sewing and after sewing. Observe the hand movement during whole operation cycle time.

Step 3: List down all motions sequentially in the operation analysis sheet.

Use a template (printed format) for recording motions. Refer to the synthetic data for TMU (Time Measuring Unit) values.

Now you have TMU values for one operation (for example, say it is 400 TMU). Convert total TMU into minutes (1 TMU=0.0006 minutes). This time is known as the Basic Time of the task in minutes. In this example, it is 0.24 minutes.

Step 4: Calculate standard minute (SAM)

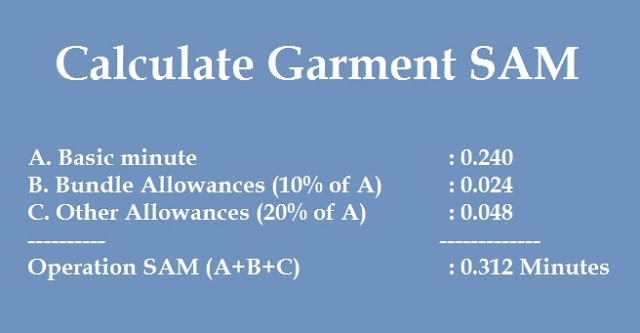

Calculate standard minute of the operation by adding the bundle allowance (bundle handling time) and personal allowance to the basic time.

Standard allowed minutes (SAM) = (Basic minute + Bundle allowances + machine and personal allowances).

Add bundle allowances (10%) and machine and personal allowances (20%) to basic time.

Now you have a Standard Minute value (SMV) or SAM.

SAM = (0.24 + 0.024 + 0.048) = 0.31 minutes.

Related Read | Secret Behind the Calculation of Machine Time in SAM

Method #2: Calculate Garment SAM Through Time Study

Step 1: Select one operation for which you want to calculate SAM.

Step 2: Take a stopwatch for the time study. Stand by the side of the operator. Capture the cycle time for that operation. (cycle time – total time taken to do all works needed to complete one operation, i.e., time from the pick-up part of the first piece to the next pick-up of the next piece).

Conduct Time study for five consecutive cycles. Discard the reading if you find an abnormal time in any cycle. Take an additional reading if you need to discard any readings.

Calculate the average time of the 5 cycles. The time you get from a time study is called cycle time. To convert this cycle time into the basic time, you need to multiply the cycle time by the operator's performance rating.

Basic Time = Cycle Time X Performance Rating

Step 3: Performance rating.

Now you need to rate the operator at what performance level he was doing the job by observing his movement and work speed. Suppose that the operator's performance rating is 80%. Assume that the cycle time is 0.60 minutes.

Therefore, Basic Time of this operation is = (0.60 X 80%) = 0.48 minute

Step 4: Calculate SAM using the following formula

Standard Allowed Minutes (SAM) = (Basic minute + Bundle allowances + machine and personal allowances).

Add bundle allowances (10%) and machine and personal allowances (20%) to basic time.

- Bundle allowances= 0.48 X10% = 0.048 minute

- Personal allowances = (0.48 x 20%) = 0.096 minute

Therefore, standard time (SAM) = (0.48 + 0.048 + 0.096) = 0.624 minutes.

The above calculation is shown in the following table.

Now, you have the Standard Allowed Minute (SAM) of the operation, which is 0.624 minutes.

Conclusion:

As an IE, you know the importance of garment operation SAM and style SAM. If you have any questions related to garment SAM calculation, feel free to contact me.

When a wholesale garment supplier plans its production, accurately calculating the Standard Allowed Minute (SAM) is essential. For a supplier producing in bulk, knowing the SAM for each sewing operation helps in estimating labor costs, setting realistic timelines, and ensuring that the pricing offered to retailers leaves enough margin. Ultimately, a wholesale garment supplier that rigorously evaluates SAM can operate more efficiently, deliver better quality control, and maintain competitive lead times without eroding profitability.