The daily production report is one of the MIS tools for operations management used in the manufacturing industry. The report I have shared here is an example of a garment manufacturing plant. The daily

production report is called a DPR.

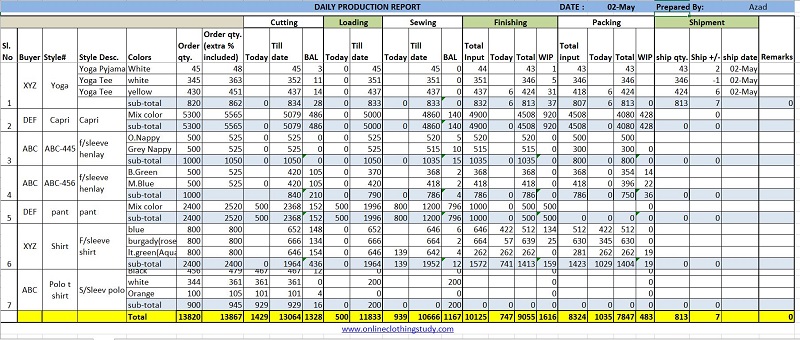

As a production manager in a factory, the first thing they need to see is the DPR report. The purpose of a DPR is to show the last production day’s garment production details by production line and by order number. Some factories further group the daily production data by supervisors, by unit. Though the major focus remains on seeing the garment stitching production data, some managers user to see the production of major processes in a factory that includes the production of cutting sections, stitching section, finishing section, packing, and quality pass quantity.

The daily production report normally includes all the ongoing production styles. This means from the styles for which cutting has been initiated to the styles which are ready to ship but not yet dispatched.

Here I have shared the daily production report format (Excel file) with instructions. Download the same and modify it if you require it.

Related post: Tips for Making a Daily Production Report Quickly

Daily Production Report by Department

The production report is prepared at various levels and in various formats by different garment units. A daily production report is normally made department-wise, and a combined production report is made including the production of all major processes.

Screenshots of the daily production report templates- Daily production report for the stitching section,

- Daily production report for the cutting section

- Daily production report for the finishing section

- Daily production report from cutting loading to order shipment

Each production department is responsible for making its production report. When it comes to making department-wise production reports, they only cover their department data. The following three production report templates are specific to the department.

Related | Custom clothing manufacturer in China

1. Daily production report for the cutting section

Order Quantity

Production average (fabric consumption)

Fabric status

Cutting production details

Cutting issue details

Order quantity – Order quantity by style

Cuttings receiving details / Cuttings loading details

- Total fabric required – Total meters (or Kgs) of fabric required for the order as per production average.

- Fabric received from store – Total fabric received from the fabric store

- Fabric balance to receive - Fabric yet to receive from the fabric store

Cutting production details

- Today cut quantity (this column shows the last production day’s data) – Number of pieces (of garments) was cut on the last production day. Cut quantity is recorded by style and color. Separate rows are used for entering color-wise cut quantity. Some cutting managers used to make reports size-wise details. This record is collected from the cutting room register or lay report.

- To date cutting quantity - Combined cutting production quantities included all the previous days cutting quantity.

- Balance pieces to cut against the order quantity (planned cut quantity including the extra cutting) – This column shows the record of the total number of pieces yet to cut to complete cutting for an order (color-wise). This is calculated as Planned cut quantity – Till date cut quantity.

Cutting issue details

- Today issues quantity – Number of cuttings sent to the stitching department on the last production date.

- To date issue qty – Total cutting quantity issues to the stitching section for all ongoing orders.

- Balance to issue against order quantity - Cut quantity is yet to issue to the stitching department. This can be presented in one of two ways. (i) Balance quantity against the planned cut quantity or (ii) Balance quantity against total cut quantities.

Figure-1: Daily cutting report

2. Daily production report for the stitching section

The stitching department’s DPR includes the following information by order, line, and style.Order quantity – Order quantity by style

Cuttings receiving details / Cuttings loading details

- Today cutting received - (this column shows the last production day’s data)

- Total cutting received - Total cutting received to date from the start of cutting issued.

- Balance pieces – Number of cuttings yet to receive from the cutting department.

- Today's production quantity – Number of garments stitched and out from the stitching line on the last production date. Production data is recorded by line and style-wise.

- Till date production – Total production quantity of the running styles till the last production date.

- Balance quantity – Balance stitching quantity can be presented in one of two ways. (i) Balance quantity against the planned order quantity including extra cutting or (ii) Balance quantity against total cutting received from the cutting department.

In the sample production report template below, I have included manpower counting as well. To know the manpower involvement on the production floor, you can include the line-wise headcount of operators, helpers, and quality checkers in the same report.

You can customize your production report depending on the processes you want to track. Capture the work loading quantity, processed quantity (production), and WIP level at the end of the day. You can also add manpower details (involved in the production in that section) in the same report as shown in the finishing report.

Another plant is used to see the fabric details of each order and the quality performance of each style on the same DPR report.

You can customize your production report depending on the processes you want to track. Capture the work loading quantity, processed quantity (production), and WIP level at the end of the day. You can also add manpower details (involved in the production in that section) in the same report as shown in the finishing report.

Advanced notes of the daily production report

The daily production report format can be extended further if someone wants to view other details on the same report. I have made the DPR report for many garment factories during MIS report preparation from the real-time production system. On the DPR, a production manager likes to see line-wise manpower involvement, total SAH produced based on style SAH and line output, line efficiency, overtime production quantity, and regular hours production quantity in separate columns. Some factories also display the number of days production is running for each style.Another plant is used to see the fabric details of each order and the quality performance of each style on the same DPR report.