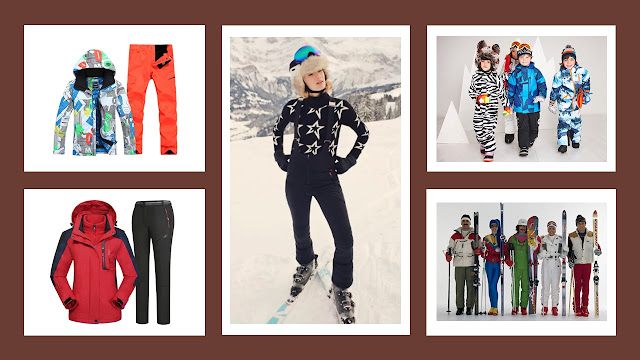

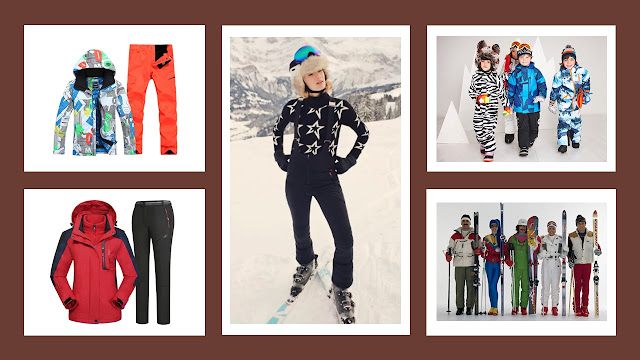

Nordic skiing and Alpine skiing account for just two types of skiing in which people participate. Skiers further engage in recreational disciplines that include cross-country skiing and Telemark skiing. Some of the popular sporting events are cross-country skiing, ski jumping and Nordic combined, which includes cross-country skiing and ski jumping (en.wikipedia.org). The business opportunity in the skiiwear manufacturing segment is discussed in this post.

There are many skiing events held annually. The FIS Nordic World Ski Championships hosts these sports, plus Telemark skiing, at the championship level in the winter of every odd-numbered year. Biathlon, which combines cross-country skiing and rifle shooting, is another event that is highly popular.

Skiwear is a somewhat untapped market segment for many of the apparel manufacturers in South Asia. This may be due to a combination of reasons. Most of these products are high SMV garments, which need longer production layouts with added machinists and helpers. In most cases, special machines, such as automatic welt pocket machines and various types and sizes of folders, are required. Another possible reason is the high investment required for the fabric and accessories. Most of the fabric prices start from $7/yard and run as high as US$65/yd. This can be a costly investment, and not many of the companies can afford to finance the fabrics.

The trims and accessories used in skiwear are carefully chosen to complement the functionality of the design. Most zippers have waterproof coatings and all seams are sealed with waterproof tapes and bindings. The wearer of these products wears gloves; hence, velcro, buttons and zippers are carefully selected to ensure compatibility with the glove hands.

Some features and specs that can be seen in skiwear are taped seams, welded pockets (radio frequency welding, or laminate welding), helmet compatible hoods, single-hand draw cord hood adjustments, stiffened laminated brims, die-cut Velcro cuffs, internal leg gators with gator hooks, full and ¾ length side-zips, vented pit zips and thigh zips, powder skirts, draw cord waists with barrel locks, Napoleon pockets with media ports, hand warmer pockets, internal dump pockets, and thumb loops on sleeves.

Skiwear designers use innovative designs to give full punctuality to the wearer. They are always looking for fabrics with quick-dry capability and fabrics with two and four-way stretch for maximum flexibility. Designers also place zippers and Velcro in unusual areas, such as under the armhole or the center of the back, for ventilation purposes.

The customers who are into ski sports are very knowledgeable about the products and appreciate the hard work gone into making them. This enables retailers to charge top dollar for the products. Essentially, this means buyers and retailers are in a position to pay higher SMR (Standard Minute Rate) for the factories who are making them. The competition for orders to be manufactured is minimal, as many companies not equipped for it. However, it is high time to look into this sector, as China is currently struggling to export to the USA due to the tariff war.

There are many skiing events held annually. The FIS Nordic World Ski Championships hosts these sports, plus Telemark skiing, at the championship level in the winter of every odd-numbered year. Biathlon, which combines cross-country skiing and rifle shooting, is another event that is highly popular.

Skiiwear Market Size

According to Statistica, the skiwear market in the USA was worth the US $6.5 billion in 2017. Europe was closely behind with another US $4.8 billion. In 2017, Europe had over 70 million people who at least participated in one ski sport; in the USA, that figure was recorded at 60 million people.Skiwear is a somewhat untapped market segment for many of the apparel manufacturers in South Asia. This may be due to a combination of reasons. Most of these products are high SMV garments, which need longer production layouts with added machinists and helpers. In most cases, special machines, such as automatic welt pocket machines and various types and sizes of folders, are required. Another possible reason is the high investment required for the fabric and accessories. Most of the fabric prices start from $7/yard and run as high as US$65/yd. This can be a costly investment, and not many of the companies can afford to finance the fabrics.

Almost all the products use high-tech functional fabrics such as PUL (Polyurethane), laminated cotton, ripstop and pro care. These are combinations and mixes of polyester, nylon, elastane and other man-made and natural fibers. These fabrics go through many different treatments that give them the added ability to function as a high-tech fabric. Most of the fabrics are made to ensure breathability, water resistance/water repellency, wind resistance and ensured protection from many other elements.

The latest development in the high-tech functional fabrics is called thirtysevenfive (described at http://thirtysevenfive.com/). This technology helps control the core temperature of the body, which is always 37.5 degree Celsius, regardless of the activity you are doing.

Fabrics used in Skiiwear product manufacturing

Some of the popular fabrics used in skiwear are Gore Windstopper, Polartec Powerstretch Pro, Pol`artec Powerstretch Pro with Hard Face, Polartec Windpro with Hard Face, Polartec Power Dry grid fleece, Polartec Powershield O2, Schoeller softshell, Keptrotec, Primaloft insulation, and Pertex Shield fabric.The trims and accessories used in skiwear are carefully chosen to complement the functionality of the design. Most zippers have waterproof coatings and all seams are sealed with waterproof tapes and bindings. The wearer of these products wears gloves; hence, velcro, buttons and zippers are carefully selected to ensure compatibility with the glove hands.

Some features and specs that can be seen in skiwear are taped seams, welded pockets (radio frequency welding, or laminate welding), helmet compatible hoods, single-hand draw cord hood adjustments, stiffened laminated brims, die-cut Velcro cuffs, internal leg gators with gator hooks, full and ¾ length side-zips, vented pit zips and thigh zips, powder skirts, draw cord waists with barrel locks, Napoleon pockets with media ports, hand warmer pockets, internal dump pockets, and thumb loops on sleeves.

Skiwear designers use innovative designs to give full punctuality to the wearer. They are always looking for fabrics with quick-dry capability and fabrics with two and four-way stretch for maximum flexibility. Designers also place zippers and Velcro in unusual areas, such as under the armhole or the center of the back, for ventilation purposes.

The customers who are into ski sports are very knowledgeable about the products and appreciate the hard work gone into making them. This enables retailers to charge top dollar for the products. Essentially, this means buyers and retailers are in a position to pay higher SMR (Standard Minute Rate) for the factories who are making them. The competition for orders to be manufactured is minimal, as many companies not equipped for it. However, it is high time to look into this sector, as China is currently struggling to export to the USA due to the tariff war.