With the ever rising growth of demand in apparel, the very idea of manufacturing had to be reshaped. This need brought about a change from a full labour-intensive industry to manufacturing done through automation. This topic will talk about what is industry 4.0 in the apparel industry and how it is impacting the fashion industry.

There are four main pillars of Industry 4.0 such as augmented reality. These 4 pillars help companies avoid errors by enabling them to manage inventory at real time; additive manufacturing such as 3-D printing and robotics which allows the companies to produce faster; big data, like IoT enables with data centralization and storage.

Automation revolution is coming into the clothing industry making a leap as it was one of the first to be mechanized. But till date machines lacked the versatility to handle soft fabric material but thanks to machine learning and various types of AI, machines are getting more versatile and are becoming capable of more complex stuff.

With machine vision systems, software and sensors visual entities like fabric pattern, shade matching, defect have been made possible to detect. With the internet of things (IoT), machines are able to communicate among them. Machines can also communicate with people in real-time to relay important information and take actions accordingly.

Cognex is an American manufacturer of machine vision system, sensors and software which can inspect the appearance of fabric patterns such as weaving, knitting, braiding, finishing and printing. What the system does is learn the weaving pattern, yarn properties, colours and tolerable imperfections from the images provided. And after a training period of few weeks the software is able to detect defects like wrong fabric pattern, printing quality, certain weaving defects saving humans from the manual task of inspecting hundreds of yards of material manually. With this, manufacturers can improve production efficiency by increasing speed, minimizing defects and reduce cost.

Datacolor offers colour management instruments and software. They have created an AI software which claims that it can perform a colour match through the sensors keeping in mind a colour tolerance. (Colour tolerance is a limit for how much the difference in colour between samples and the original requirement). The real-life applications of this are immense for the entire supply chain to improve colour development and apparent to provide accurate colour matching.

The first step for a totally automated production system has been brought about from a company called SoftWear Automation. Their computer vision powered robot SewBots which has the ability to sew footwear, t-shirts pillows, bath mats, automotive mats, etc. It has solved the problem with material handling by making the sewing needle move around the fabric and not the other way around. With present technology, only the mass production of the t-shirt has been made possible reducing the time to 22 seconds. Only one operator can produce the same number of t-shirts as 17 manual sewers.

Just have a look.

Video source: https://www.youtube.com/watch?v=qXFUqCijkUs

A company in Japan YOHO is taking an intermediately steps in automation replacing sewing machines to machines that aid the process of sewing by automating some of the most time-consuming steps. With their machines, anyone can perform a difficult sewing operation which otherwise would require a skilled operator with a greater amount of time. The machines are controlled by computer and can maneuver over any pattern, shape, sizes automatically. In addition to automated sewing, folding, cutting, and pressing their machines can automatically detect different fabrics sizes and patterns along with switching between different functions and settings. This can act as a stepping stone towards total automation with further improvement in technologies.

Some companies like Lectra have already started influencing the fashion and apparel industries towards Industry 4.0. For them, this new manufacturing system will be able to combine customer’s demand and the ability for customization converting large scale production to smaller run production with higher profit. To them preparing for Industry 4.0 would require companies to digitize their supply chain to achieve enterprise-wide transparency by connecting systems, process and people together.

With all the advantages, Industry 4.0 still at present is not popular throughout the industry. The investment over making a smart factory is too high for small industries thus making its implementation limited. Moreover, adaptations of all these technologies in the apparel industry are still at its early stage making it limited to even the developed countries.

Industry 4.0 also brings some big questions on our mind, “what will happen to most of the employees in the industry when automation will reach its full potential? What will happen of the developing countries like Bangladesh, middle east countries whose economy depends on the apparel industry?

Also see: The global summit on Apparel 4.0, Shaping the future with smart factories - Few pointers

Concluding to Industry 4.0, it is still at its very early stage in the apparel industry. With improvements in technology like AI, machine learning, big data etc. It will be soon when we will see an apparel industry with no people working. But how long it is going to take for that remains a question and on the idea that we even want this or not.

An interesting article related to this topic: Automated Couture: Using Robots to Make Clothing

References:

https://sourcingjournal.com/

https://www.techemergence.com/

What is Industry 4.0?

Industry 4.0 is the common term for modern industrialization. This is leading to automation and data exchange in manufacturing technologies. It includes entities like cyber-physical systems, internet of things (IoT), cloud computing, artificial intelligence (AI) etc. All these tools have made it possible for what is called ‘smart factory’.There are four main pillars of Industry 4.0 such as augmented reality. These 4 pillars help companies avoid errors by enabling them to manage inventory at real time; additive manufacturing such as 3-D printing and robotics which allows the companies to produce faster; big data, like IoT enables with data centralization and storage.

Automation revolution is coming into the clothing industry making a leap as it was one of the first to be mechanized. But till date machines lacked the versatility to handle soft fabric material but thanks to machine learning and various types of AI, machines are getting more versatile and are becoming capable of more complex stuff.

With machine vision systems, software and sensors visual entities like fabric pattern, shade matching, defect have been made possible to detect. With the internet of things (IoT), machines are able to communicate among them. Machines can also communicate with people in real-time to relay important information and take actions accordingly.

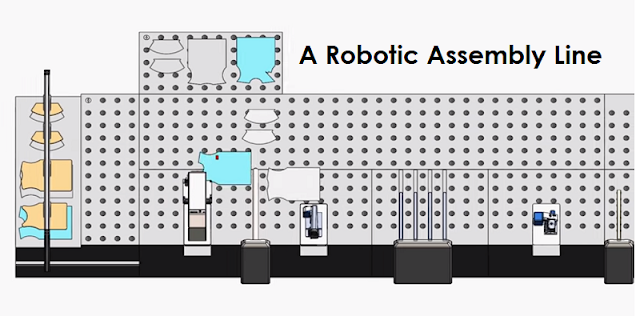

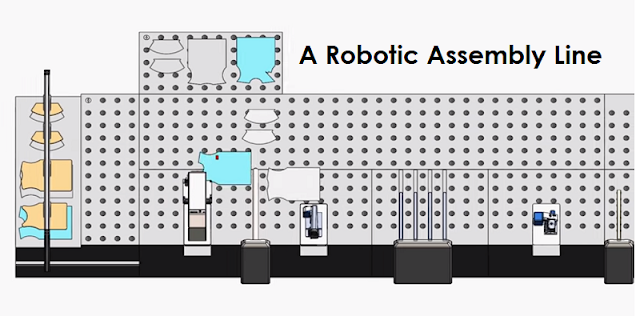

Industry 4.0 technology and implementation

Below are some of the technologies that are presently available which promises the future of Industry 4.0 in the apparel industry.Cognex is an American manufacturer of machine vision system, sensors and software which can inspect the appearance of fabric patterns such as weaving, knitting, braiding, finishing and printing. What the system does is learn the weaving pattern, yarn properties, colours and tolerable imperfections from the images provided. And after a training period of few weeks the software is able to detect defects like wrong fabric pattern, printing quality, certain weaving defects saving humans from the manual task of inspecting hundreds of yards of material manually. With this, manufacturers can improve production efficiency by increasing speed, minimizing defects and reduce cost.

Datacolor offers colour management instruments and software. They have created an AI software which claims that it can perform a colour match through the sensors keeping in mind a colour tolerance. (Colour tolerance is a limit for how much the difference in colour between samples and the original requirement). The real-life applications of this are immense for the entire supply chain to improve colour development and apparent to provide accurate colour matching.

The first step for a totally automated production system has been brought about from a company called SoftWear Automation. Their computer vision powered robot SewBots which has the ability to sew footwear, t-shirts pillows, bath mats, automotive mats, etc. It has solved the problem with material handling by making the sewing needle move around the fabric and not the other way around. With present technology, only the mass production of the t-shirt has been made possible reducing the time to 22 seconds. Only one operator can produce the same number of t-shirts as 17 manual sewers.

Just have a look.

Video source: https://www.youtube.com/watch?v=qXFUqCijkUs

A company in Japan YOHO is taking an intermediately steps in automation replacing sewing machines to machines that aid the process of sewing by automating some of the most time-consuming steps. With their machines, anyone can perform a difficult sewing operation which otherwise would require a skilled operator with a greater amount of time. The machines are controlled by computer and can maneuver over any pattern, shape, sizes automatically. In addition to automated sewing, folding, cutting, and pressing their machines can automatically detect different fabrics sizes and patterns along with switching between different functions and settings. This can act as a stepping stone towards total automation with further improvement in technologies.

Some companies like Lectra have already started influencing the fashion and apparel industries towards Industry 4.0. For them, this new manufacturing system will be able to combine customer’s demand and the ability for customization converting large scale production to smaller run production with higher profit. To them preparing for Industry 4.0 would require companies to digitize their supply chain to achieve enterprise-wide transparency by connecting systems, process and people together.

With all the advantages, Industry 4.0 still at present is not popular throughout the industry. The investment over making a smart factory is too high for small industries thus making its implementation limited. Moreover, adaptations of all these technologies in the apparel industry are still at its early stage making it limited to even the developed countries.

Industry 4.0 also brings some big questions on our mind, “what will happen to most of the employees in the industry when automation will reach its full potential? What will happen of the developing countries like Bangladesh, middle east countries whose economy depends on the apparel industry?

Also see: The global summit on Apparel 4.0, Shaping the future with smart factories - Few pointers

Concluding to Industry 4.0, it is still at its very early stage in the apparel industry. With improvements in technology like AI, machine learning, big data etc. It will be soon when we will see an apparel industry with no people working. But how long it is going to take for that remains a question and on the idea that we even want this or not.

An interesting article related to this topic: Automated Couture: Using Robots to Make Clothing

References:

https://sourcingjournal.com/

https://www.techemergence.com/