This article covers different types of presser foot used in sewing machines. Images of the different types of sewing machine presser foot are shown here with the use of these feet.

What is a presser foot

A pressure foot is an attachment used with the sewing machine to hold the fabric flat as it is fed through the needle and stitched. The movement of the fabric in both front and back direction is made possible as the feed dog with its motion presses up against the pressure foot and the sewer provides extra support to the fabric by guiding it with one hand.

The pressure foot keeps the fabric flat so that it does not rise and fall with the needle and pucker as it is stitched. The pressure foot is often single hinged to provide flexibility as the workpiece moves beneath it.

Pressure foot is of numerous types often specialized to adjust with different types of working material, different types of stitches, seams, etc. The most commonly used pressure foot is the all-purpose foot and the zipper foot. Following are the different types of the specialized foot along with their functions.

Pressure foot is of numerous types often specialized to adjust with different types of working material, different types of stitches, seams, etc. The most commonly used pressure foot is the all-purpose foot and the zipper foot. Following are the different types of the specialized foot along with their functions.

Related: Different Types of Industrial Sewing Machines and Their Use

1. All-purpose foot

The all-purpose sewing foot as the name indicates can be used for any type of sewing. It is most often used in straight single needle machines. It is the most basic of sewing foot and does not include any work aids for easing of tasks.

|

| All-purpose sewing machine presser foot |

2. Satin foot

It is used for decorative stitching as the stitches have to be dense. This is most commonly used in appliques.

|

| Satin foot |

3. Zipper foot

This is one of the most common foot and its narrow foot allows for close stitch around the zipper.

|

| Zipper foot |

4. Sew-easy foot

Helps you sew in straight lines, no matter what seam allowance you need. The foot has a "ruler" with an adjustable guide for precision. The foot has a "ruler" with an adjustable guide for precision. For beautiful topstitching, place the guide along an already stitched seam or against an edge.

|

| Sew easy foot |

5. Adjustable zipper cording foot

It has a screw at the back making it possible to move the foot manually to the left or right. It is most often used for piping and cording as the foot can be adjusted manually so that it can be sown very closely to the piping when creating or inserting it.

|

| Adjustable foot |

6. Blind hem foot

Blind hem foot makes it easier to sew a hem on garments. There are various styles of blind hem feet but what they have in common is an extension at the front of the foot for guiding the fabric fold.

|

| Blind hem foot |

7. Overedge foot

Overedge foot is used when adding a seam finish at the edge of a seam allowance. There is a small bridge in the foot which allows more thread into the stitch. Fabric is guided along with the extension at the front of the foot.

|

| Over-edge presser foot |

8. Button stitch foot

Button stitch foot is used to easily attach buttons whether they are 2 hole or 4 hole buttons. It holds the button securely in place while a zigzag stitch is used to attach the button. If the machine has a drop feed lever lower the feed dogs, if not use a feed dog cover plate over the feed dog or simply put the stitch length to zero.

|

| Button stitch foot |

9. Darning embroidery foot

This kind of presser foot is used for free motion work like stippling.

|

| Embroidery presser foot |

10. Even feed foot

The even feed foot is sometimes called the walking foot or dual feed foot. It works just like another set of feed dogs helping to feed the fabric to the stitching area. Use this foot to prevent shifting of coat layers or shifting of seams in fabric like velvet or corduroy. It is also used heavier material as only the feed dog is not enough to feed the material through the needle.

|

| Even feed foot |

Related: Resources for sewing machine folders and attachment

11. Quarter inch foot

The quarter inch foot is most commonly used for quilting but can also be used for craft sewing. Use the edge of the pressure foot as a guide for sewing ¼ inch seam.

|

| Quarter inch foot |

12. Open toe foot

The open toe foot has a large open area in the front of the foot providing a large view of your work which is very helpful when decorative stitching or coaching over ribbons and trims.

|

| Open toe foot |

13. Edge joining foot

The edge joining foot is used for joining trims or fabrics.

|

| Edge joining foot |

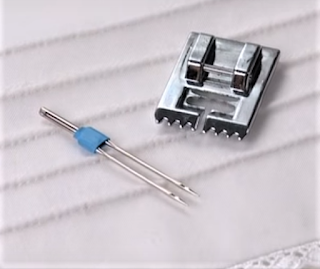

14. Pintuck foot

The pintuck foot has several evenly spaced grooves on the bottom which allows for sewing parallel rows of stitching closely together. It is used along with twin needle to create a wonderful surface texture on the fabrics very commonly found in many garments and home accessories.

|

| Pintuck foot |

15. Ruffler foot attachment

The ruffler foot attachment is used to create perfectly spaced pleats and gathers at set intervals. It can be used for light-weight as well as medium weight fabrics.

|

| Ruffler foot attachment |

16. Gathering foot

The gathering foot is simply designed to create fullness in soft light well fabrics.

|

| Gathering foot |

17. Cording foot

The cording foot has grooves on the top which are used to guide a yarn or cord. Stitches are sewn over cords placed into the foot as the foot guides them evenly, the gathering can also be done through this foot.

|

| Cording foot |

18. Sew and serge foot

The sew and serge foot is also known as the side cutter trims the excess fabric while sewing.

|

| sew and serge foot |

There are many other types of pressure foot specialized for various tasks. Most pressure foots are made of steel or clear plastic, but for sewing leather, plastic, vinyl, oilcloth pressure foot made of Teflon or other non-stick materials are also used. To make the transition easier for the pressure foot they are equipped with easy snap features like:

- Some simply snap on or off the machine.

- Some are removed by pressing a lever or release button on the shank.

- Others are attached to the shank and need to be removed together with a small screwdriver.

- Some have the shank already attached and have to be removed completely to put the new foot on.