T&A (Time and Action) calendar can act as the backbone of the apparel organisations when it is implemented smartly. Time and Action calendar is a tool that helps in planning what needs to be done, when it needs to be done, by whom it needs to be done, the time it will take and what resources are required to do it. Maintaining and tracking a T&A manually, however, can be extremely tedious and cumbersome.

Hence, here are a few hacks that might provide you an insight on how to use your T&A to its maximum effectiveness. Post implementing these, you might be surprised to find out how powerful your T&A is.

1. Set up milestone activities

The tasks and deadlines should focus on some key milestones (e.g. PP Sample approval, Lab Dip approval, Planned Cut Date, Ex-Factory Date). Tracking all other activities against the milestone activities proves to be more efficient than tracking all activities individually. For example, if the deadline set for PCD is met, one day delay in sample approval won’t have much of an impact.

2. Track key milestones weekly

It is important to meet once in a week to discuss the performance of the milestone activities and communicate the point of the meetings to all stakeholders involved. This is imperative in order to maintain transparency and consistency.

3. Mineable data

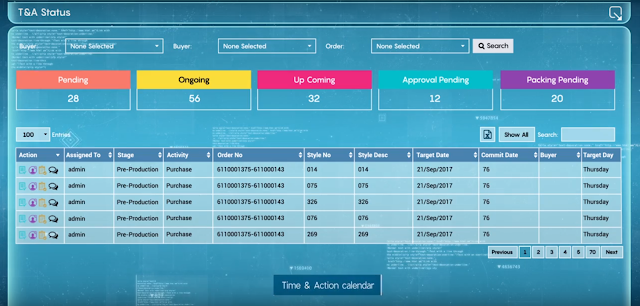

All the information relating to decisions and corrective actions should be recorded in a tracking tool that is smart and easy to use. It should be possible for the user to store and retrieve information as and when necessary.

4. Be relevant

Too many details can lead to redundancy and confusion. Smart management should always be preferred over micromanagement.

5. T&A is different from Excel Spreadsheet

T&A is not only used as a calendar but can be used to keep real-time track of all activities and build transparency by ensuring seamless communication across all stakeholders.

Benefits of T&A

As per BlueKaktus, following the above key points while implementing and maintaining T&A can yield humongous business benefits. Some of them are listed below-

Related Post: How to Make Production Planning Task Easier?

- Improved merchandiser productivity (by over 100%)

- Reduced Lead times (by 15%)

- Enhanced buyer’s trust by enabling them better control of their inventory

- Significant cost savings (of 5-8% % in a span of 6 months post-implementation through a reduction in inventory, manpower, and delays)

- Increased OTIF leads to higher customer satisfaction, leading to higher trust from customers and greater business from them.

Related Post: How to Make Production Planning Task Easier?