Body coveralls, a Personal Protective Equipment (PPE), are critical for frontline healthcare workers to control and prevent infection. These create a barrier to eliminate or reduce contact and droplet exposure, and are designed such that the whole body is covered to provide an out-and-out protection from exposure to the virus.

The PPE market has been characterised by a surge in global demand and thus put more pressure on the supply chain, resulting in a restrain on supply of raw materials. The choice of raw material- fabric for the manufacture of PPE needs to be appropriate, such that it furnishes uncompromised safety and comfort through penetration resistance and breathability respectively.

The specifications for coveralls are:

- Impermeable to blood and body fluids

- Virus resistant

- Comfort of wear

- Single use (disposable) or heavy duty reusable waterproof apron

- Colour- Light colours are preferable to better detect possible contamination. Avoid culturally unacceptable colours e.g. black.

- Quality compliant- As per test standard for demonstrating the fabric performance of protective garments against infective agents

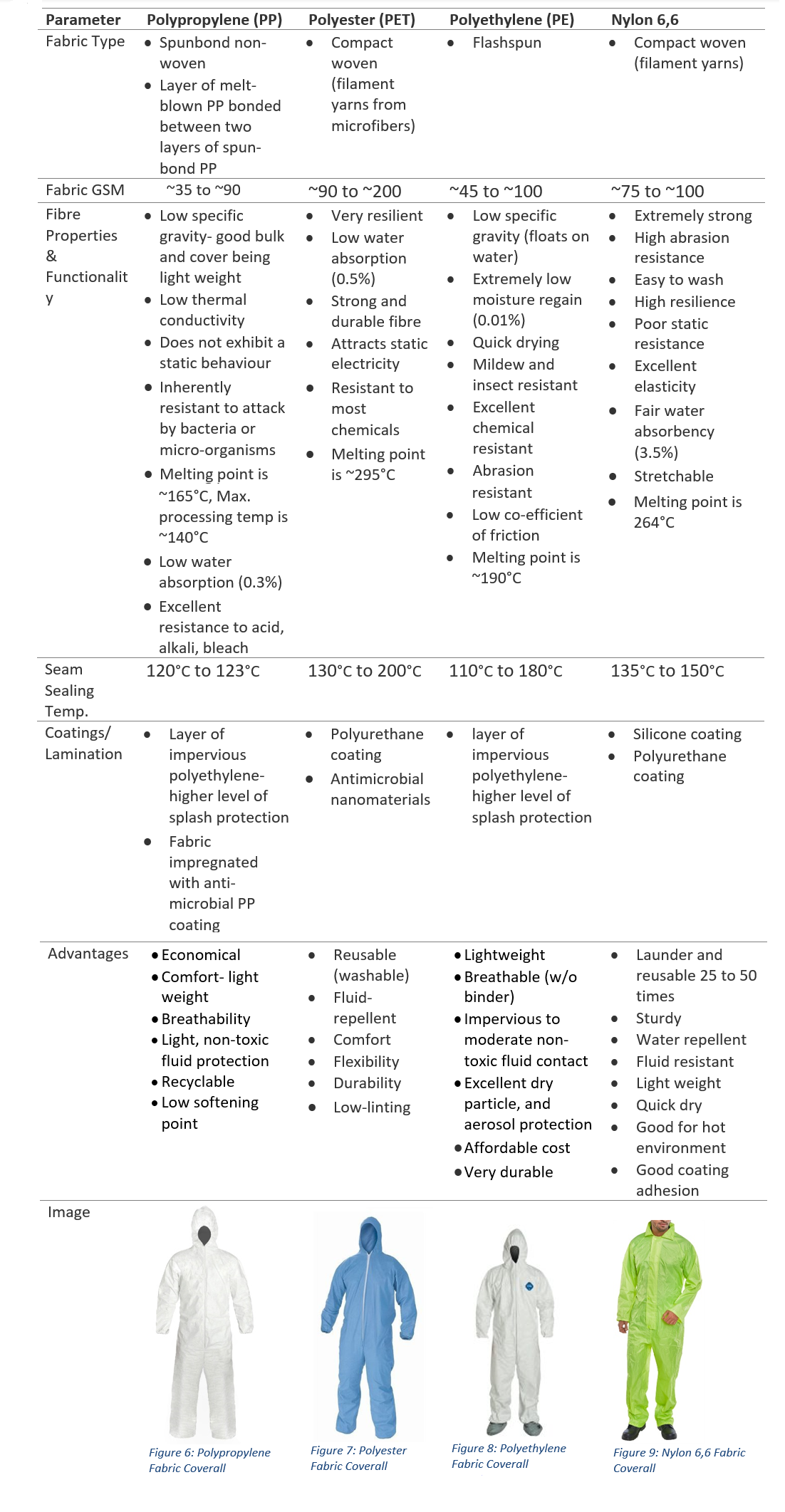

The fabric material for manufacturing PPE coverall are synthetic fibres, such as, polypropylene (PP), polyester (PET), polyethylene (PE), and nylon 6,6.

Here, the materials are compared with respect to the following parameters:

Fabric Type

The fabric type is mainly non-woven, which are single-use. However, there have been some developments with woven fabric to increase the durability and number of uses.

Fabric Weight

The weight of the fabric (gsm) is determined by the weights of both the substrate layer and the coating/ laminate film. Fabric thickness and weight have an effect on protection and overall comfort. Generally, the heavier the fabric, the higher is the level of physical strength and fluid resistance.

Properties and Functionality

The physical and chemical properties of the fibre that make them suitable for use in PPE coverall fabric. The material needs to have the quality of being suited to serve the purpose of complete protection against penetration of infectant, antibacterial, oil and water repellence, and fluid resistant, while at the same time offering comfort to the wearer.

|

| Figure 2: Properties of Fabric for Coveralls |

Comfort Aspect

The fabric needs to be breathable in a way to ensure comfort of healthcare professionals working in a hot and humid environment without air conditioning. Fabric weight is a critical factor in determining the comfort in terms of tactile factors.

|

| Figure 3: Disposable coverall to provide both protection and breathability | Source: uvex-safety.com |

Seam Sealing Temperature

The nozzle temperature of hot air seam sealing machines is set as per fabric and tape material. The jaw temperature of the seam-sealing machine should be at least 10 °C higher than the melting point of the material for an adequate seam to be formed. The temperature generally ranges from around 260°C to 350°C. A lower seam sealing temperature saves energy.

|

| Figure 4: Hot-Air Seam Sealing |

Coating/ Lamination

Coating or lamination provides the additional functionality of fluid resistance, antibacterial property, antiviral property, etc.

|

| Figure 5: PE Laminate Film on PP fabric |

The details of the parameters for the respective materials are mentioned in the table below.

Related post: Different types of fabrics used in making facemasks

References:

- Pradhan, D., Biswaroy, P., Naik, P. K., Ghosh, G., & Rath, G. (2020). A Review of Current Intervention for COVID-19 Prevention. Archives of Medical Research.

- Zhao, M. & Lu, L.. (2008). Effect of heat sealing temperature on heat-sealing performance of PET/Al/PE packaging laminated film. 25. 57-61.

- https://www.unicef.org/supply/stories/covid-19-impact-assessment-and-outlook-personal-protective-equipment

- https://www.bsigroup.com/LocalFiles/en-GB/Blogs/BSI-technical-guide-medical-protective-clothing-en-uk.pdf

- https://www.dupont.com/brands/tyvek.html

- https://www.astm.org/COVID-19/

- https://forcetechnology.com/en/services/test-approval-personal-protective-equipment-ppe

- https://qz.com/1837127/ford-turns-airbag-material-into-ppe-for-covid-19-responders/

- https://www.amazon.co.uk/Seam-Sealing-Tape-T-2000X-Waterproof/dp/B00YP68TVM

- https://www.packagingdigest.com/medical-packaging/pmp-sealing-parameters-for-polyamide-pouches-141118