Safety has always been in priority and when it comes to children and if not considered the garments that they are wearing can make a huge compromise to that. As a result, apparel brands and government bodies have made stringent safety measures to ensure that the garments made and sold for children are devoid of any such components. The following article discusses in brief about such safety measures that a children’s garment must comply to make them safe and secure to wear.

Out of all the age groups for apparel, it would be correct to say that children between age 3years or under are most vulnerable to various hazards from the clothes they are wearing. Thus apparel brands should be responsible for the safety and in doing so maintain its commitment towards quality and safety in their products. This led to several rules and guidelines made for designing the garments and components that are to be attached to it. This information and guidelines are for the manufacturers and sellers to implement them in the designing and manufacturing of the product so that they meet and exceed those criteria. And any compromise in that can have a legal impact on the seller which can sabotage the brand’s reputation.

Children garments often consist of different types of trims and attachments to make them more adorable and suitable for children. But these also pose a great deal of danger to the children through different risks such as choking, entanglement, suffocation, ingestion etc. Following are components that are attached to the garments with the different safety measures and potential risks that they possess.

Fig-1: Food shaped buttons and multi-component buttons

Fig-2: Tassels and Pom-poms

Fig-3: Bows

Fig-4: Sequins and Beads

It is always preferable not to have any functional zipper in clothing especially in the fly area for children of 5yrs and under and if used should comprise of plastic slider and elements.

Fig-6: tact button, rivet, Hook & Bar

Fig-7: Drawstring at neck

Fig-8: Body zones | Pic Ref: Safety of children’s clothing by TÜV SÜD

Zone A: Head, neck and upper chest area

Any kind of string or cord is not permitted in these regions as they can lead to injuries or strangulations if they get trapped at any surrounding objects. In a garment, these places include mostly hoods, neck cords, halter neck strings, decorative cords around neck or hood, shoulder straps, etc. It is always advisable not to have free ends for drawstrings and thus use of toggles for adjustment. And for such loops, when the garment is opened to its largest there shall be no protruding loops and when the garment is at its smallest opening position the loop circumference shall not be more than 15cm. Else for any kind of functional cord, the length should not exceed 7.5cm and should not be of elastic.

For shoulder strap, there should not be any free ends when the garment is worn and for the decorative cords attached, the free ends should not be more than 7.5cm which is same for the circumference of any fixed loop. What can be done is the use of permanently fixed straps, use of buttons, press fasteners, clips, ring and slider mechanism.

Zone B: Chest and waist area

In such zones, drawstrings, functional cords, decorative cords, fabric belts should not be more than 20cm for bottoms and 14cm for tops for both ends when the garment is in a relaxed state. In garments, these include drawstrings at waist for trousers and jackets, decorative cords around the region, protruding loops with toggles etc. These can be trapped at any surrounding object and can cause injury.

Zone C: Below hip area

Any kind of drawstrings should not hang below the lower edge of the garment and should lie flat against the garment when it is tightened or fastened. Also, fringes at the bottom hem are considered as decorative cords and should be discouraged for use.

Zone D: Back area and sleeves

For children’s garment, there should be no drawstrings or functional cord emerging from the back or being attached at the back. Any kind of decorative cords present should not be more than 7.5cm of length and should not have any knots, toggles, or any other 3D embellishments as these can cause discomfort.

For both long and short sleeves, any kind of cords should be more than 7.5cm in length. For long sleeves, the drawstrings should be faced towards the garment and if positioned below the elbow should not hang below the lower edge of the sleeves. For short sleeves, these are permitted if the sleeve finishes above the elbow

Fig-9: Thedomesticdiva

Elastics: Elastics can be very dangerous in certain zones in children's clothing as it leads to suffocation and discomfort. The elastic selected be in accordance with the garment pattern to ensure the proper length of the elastic used. It should not be too tight to add to discomfort or too loose to not hold the garment in place.

Velcro: The positioning of the Velcro should be such that hook side faces opposite to the skin to prevent skin abrasion to the child. It is also suggested that it is die-cut with rounded corners to minimize the risk of scratching.

Magnets: For usual reasons, the garments should be devoid of any magnets.

For testing these objects, they are placed in small parts cylinder and if the item in consideration falls/fits into the cylinder without any external help, it is considered a potential choking hazard. Upon so these must be able to withstand a certain amount of pull force for them to be used in the garment. According to US standard, these components should be able to withstand a pull force of 15-21lbs to be able to use in the garment of children of 3yrs and under.

To ensure such criteria are met it is always advisable to source such materials from approved sources such as YKK, Scovill Fasteners Inc., Morito, Prym etc.

All the above guidelines are made so that there are no potential risks and hazards from the garments that the children are wearing. More detailed explanations about this can be found in the various Industrial standards and Government consumer product safety guidelines. It is also to be kept in mind that these guidelines often vary according to countries and complying to them is a must for any manufacturer and brands who wishes to sell such products in those countries.

The other purpose of this article is to make the general people aware of the risks from the components used in children’s garment so that they can make correct purchase decisions for the garments that they are buying for their children.

References:

Children garments often consist of different types of trims and attachments to make them more adorable and suitable for children. But these also pose a great deal of danger to the children through different risks such as choking, entanglement, suffocation, ingestion etc. Following are components that are attached to the garments with the different safety measures and potential risks that they possess.

Safety measures and potential risk with Trims and attachments

Buttons

These are knobs or disks attached to the garment and are used for garment fastening or as decoration. For these to be used in children’s garment these must be able to withstand 70N of force before rupturing or breaking. Also, these should not have any sharp edges on any side to minimize the risk of any cutting or scratching. Also, care has to be taken for multi-component buttons as on separation it can add to the risk due to small parts. The design of the button should not resemble any food as it can attract the children. Also, attachment of the spare buttons should be secured inside the garment.

Fig-1: Food shaped buttons and multi-component buttons

Pom-pom and tassels

These are components which should always be avoided in the garments as they are more prone to sucking by the children. Thus they should have high fastness to saliva and moisture. These should also be very durable to prevent unravelling of the yarns at loose ends and should be securely attached to the garment. These are to be secured to the garment to withstand a minimum pull force of 70N and these are not to be attached to the end of drawstrings, cord or tie with free ends.

Fig-2: Tassels and Pom-poms

Fabric embellishments such as bows and labels

For any kind of fabric embellishment, the end of the fabric should be heat sealed to prevent yarn to unravel. For labels and badges, they have to be laser cut without any sharp edge and should not degrade on exposure to pulling or laundry. There is also the predefined length of such embellishments like for hood area, the loop can be 4cm in length and tail 2.5cm while for waist area the length cannot be greater than 7.5cm. They must be secured tightly enough to withstand the force of 70N and should be tested for colour fastness.Fig-3: Bows

Sequins, beads and similar components

Any of the above components should be securely attached to the garment such that it lays flat. Machine stitch which is considered the most durable should be preferred along with hand stitch but it is recommended to lock it off after every 10 stitches. These should be stitched with core-spun polyester with double thread and knotted end.

Fig-4: Sequins and Beads

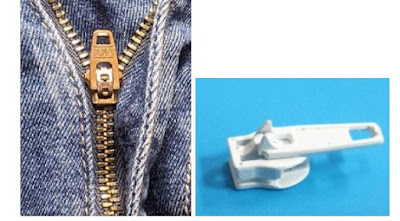

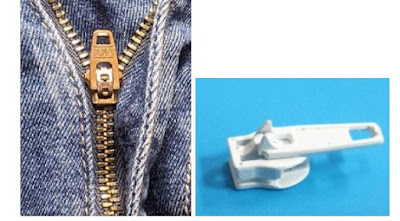

Zippers

Zippers should always be sourced from approved sources for higher quality material and with all the necessary components like slider, top stop, bottom stop, tape etc. These components should not be individually sourced for self-assembly. To ensure that zipper or its component do not pull apart and securely attached, it must be able to withstand 70N of force. These should be free from any toxic substance which mostly is as surface coating and has to comply with standards available for it. These must also have an auto-lock or semi-auto lock slider as pin lock zippers are not acceptable for children’s wear. Also, all the edges and components have to be smooth and finished along with being durable to any kind of material degradation. Most importantly the zip guard should at least be 20mm wide, securely attached across the fly opening to prevent against accidental entrapment of the penis in boy’s trousers. The use of concealed/invisible zippers are also not permitted along with indirect attachment zipper pulls for children’s clothing.It is always preferable not to have any functional zipper in clothing especially in the fly area for children of 5yrs and under and if used should comprise of plastic slider and elements.

Fig-5: Zipper and Pinlock Zipper

Press fasteners and similar applied components

Press fasteners and other components such as tack buttons, rivets, eyelets, hooks and bars should be firmly secured to the garment and should be able to withstand a pull force of 70N. the placements should also be such that there is no discomfort to the body as it can lead to discomfort and reddening on the skin with rashes.

Fig-6: tact button, rivet, Hook & Bar

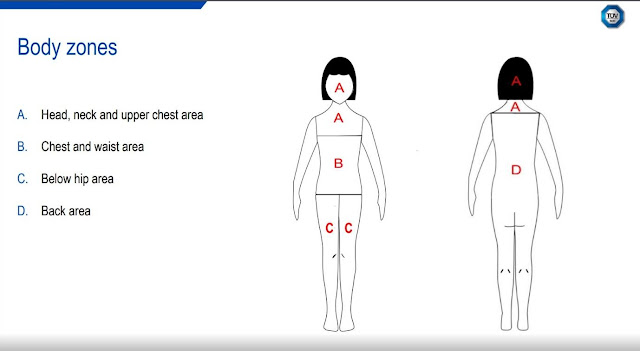

Cords, strings, ribbons, and bows

The above trims can be present in any location on the body such as neck, wrist, ankle, waist, back etc. and each location has its criticality for potential hazard. To cater to this children’s body has been divided into body zones and based on these safety measures has been defined.Fig-7: Drawstring at neck

Fig-8: Body zones | Pic Ref: Safety of children’s clothing by TÜV SÜD

Zone A: Head, neck and upper chest area

Any kind of string or cord is not permitted in these regions as they can lead to injuries or strangulations if they get trapped at any surrounding objects. In a garment, these places include mostly hoods, neck cords, halter neck strings, decorative cords around neck or hood, shoulder straps, etc. It is always advisable not to have free ends for drawstrings and thus use of toggles for adjustment. And for such loops, when the garment is opened to its largest there shall be no protruding loops and when the garment is at its smallest opening position the loop circumference shall not be more than 15cm. Else for any kind of functional cord, the length should not exceed 7.5cm and should not be of elastic.

For shoulder strap, there should not be any free ends when the garment is worn and for the decorative cords attached, the free ends should not be more than 7.5cm which is same for the circumference of any fixed loop. What can be done is the use of permanently fixed straps, use of buttons, press fasteners, clips, ring and slider mechanism.

Zone B: Chest and waist area

In such zones, drawstrings, functional cords, decorative cords, fabric belts should not be more than 20cm for bottoms and 14cm for tops for both ends when the garment is in a relaxed state. In garments, these include drawstrings at waist for trousers and jackets, decorative cords around the region, protruding loops with toggles etc. These can be trapped at any surrounding object and can cause injury.

Zone C: Below hip area

Any kind of drawstrings should not hang below the lower edge of the garment and should lie flat against the garment when it is tightened or fastened. Also, fringes at the bottom hem are considered as decorative cords and should be discouraged for use.

Zone D: Back area and sleeves

For children’s garment, there should be no drawstrings or functional cord emerging from the back or being attached at the back. Any kind of decorative cords present should not be more than 7.5cm of length and should not have any knots, toggles, or any other 3D embellishments as these can cause discomfort.

For both long and short sleeves, any kind of cords should be more than 7.5cm in length. For long sleeves, the drawstrings should be faced towards the garment and if positioned below the elbow should not hang below the lower edge of the sleeves. For short sleeves, these are permitted if the sleeve finishes above the elbow

Fig-9: Thedomesticdiva

Heat fused components

These are several factors on which its performance depends such as fabric texture, fabric elastic, fabric finish, uneven surface etc. but the fusing should be durable enough not to chip off on usage and laundering process.Elastics: Elastics can be very dangerous in certain zones in children's clothing as it leads to suffocation and discomfort. The elastic selected be in accordance with the garment pattern to ensure the proper length of the elastic used. It should not be too tight to add to discomfort or too loose to not hold the garment in place.

Velcro: The positioning of the Velcro should be such that hook side faces opposite to the skin to prevent skin abrasion to the child. It is also suggested that it is die-cut with rounded corners to minimize the risk of scratching.

Magnets: For usual reasons, the garments should be devoid of any magnets.

Choking from small parts

Among all the above the smaller components always possess the threat of being detached from the garment and consumed by the children leading to choking, asphyxiation and ingestion hazard. These smaller components mainly consist of:- Dungaree clasps(Hasps) and slider

- Belt fastenings

- Buttons

- Toggles

- Decorative labels

- Decorative and functional loops

- Zipper and its parts

- Snaps/studs/rivets

- Bows and rosettes

- Pompoms and fringes

For testing these objects, they are placed in small parts cylinder and if the item in consideration falls/fits into the cylinder without any external help, it is considered a potential choking hazard. Upon so these must be able to withstand a certain amount of pull force for them to be used in the garment. According to US standard, these components should be able to withstand a pull force of 15-21lbs to be able to use in the garment of children of 3yrs and under.

Surface finishing in attached trims and components

All metal and non-metal components which includes components like metal fasteners, such as press fasteners(prongs), press fasteners(post), stud buttons, eyelet, rivet, zipper, must be free of any toxic elements. Different countries have and follow different standards among which in the US the toxic elements must comply to ASTM F963 and for Canada, it must be checked against Hazardous products act. The surface finishing used should also be complied against lead and phthalates requirement according to a different region and its standards. The surface coating used should also be able to withstand washing and dry-cleaning process in accordance to care label and do not dissolve or chip off from the surface. Along with this, the material used must also not degrade in time with corrosion, oxidations, rust formation, etc. as it can compromise the aesthetics and more important the durability of the material.To ensure such criteria are met it is always advisable to source such materials from approved sources such as YKK, Scovill Fasteners Inc., Morito, Prym etc.

Withstand abuse from external sources

All the attached trims and components must be able to withstand physical abuse from sources such as washing, dry-cleaning, pulling, etc. and do not detach or tear from the garment. If so it can cause great compromise to the safety of the garment. To check for such all such trims should be able to withstand a minimum force of 70N before any kind of distortion in shape or damage.Conclusion:

Any of the components used should not be detected through any metal detector.All the above guidelines are made so that there are no potential risks and hazards from the garments that the children are wearing. More detailed explanations about this can be found in the various Industrial standards and Government consumer product safety guidelines. It is also to be kept in mind that these guidelines often vary according to countries and complying to them is a must for any manufacturer and brands who wishes to sell such products in those countries.

The other purpose of this article is to make the general people aware of the risks from the components used in children’s garment so that they can make correct purchase decisions for the garments that they are buying for their children.

References:

- Quality Characterization of Apparel by Dr Subrata Das

- https://www.tuvsud.com/en/-/media/global/pdf-files/webinar-presentations/tuv-sud-safety-of-childrens-clothing-cords-and-drawstrings.pdf?la=en&hash=FE46D6BC4311551A76EDBDF92DA79F36

- https://www.cpsc.gov/Regulations-Laws--Standards/Statutes/The-Consumer-Product-Safety-Improvement-Act

- https://www.bsigroup.com/en-IN/

- https://www.nra.net.au/app/uploads/2015/06/Product-Safety-Childrens-Apparel-Accessories-Product-Safety-Guidelines.pdf

- https://www.compliancegate.com/children-clothing-regulations-european-union/