As we all know in today’s scenario (after pandemic), we all need to offer a little extra and work more efficiently to stay in competition. Either we offer products at less price or deliver goods at a faster rate than the competitor. If not we will be out of the market in no time. As raw material (fabrics) and labor cost are increasing day by day. So, reducing cost is not an easy task.

To reduce the cost we must find ways to eliminate non-value added activities from the system and achieve 100% FTR. Rejection and rework amounts to a big percentage of wastage which is neglected by many factories.

To reduce the cost we must find ways to eliminate non-value added activities from the system and achieve 100% FTR. Rejection and rework amounts to a big percentage of wastage which is neglected by many factories.

Related post: How to control garment rejection rate in garment manufacturing?

About the Author

Shobhit Jindal is a graduate from NIFT with a degree in apparel production. He has done his MBA from Amity University in Operations. He has a total experience of years in apparel industry in field of industrial engineering, Quality control and Audit, Production and Product Development.

Sampling is one of the most ignored areas, when it comes to planning of garment deliveries. We fail to incorporate required sampling time while planning and later suffer at the time of delivery blaming each other and asking extension from customer. Moreover sample rejection (which is very common) makes the situation worse.

Challenges faced during sampling which results in delay in sample or rejection (internal or external) of sample:

The following measures can be incorporated so as to eliminate above mentioned challenges during sampling:

This sheet will help to collect all required information from customers in one go. Either we can send this to the customer to fill or we can collect information from him through mail or call. This checklist can be updated at regular intervals as per requirement.

It will eliminate any chances of error which can cause any issue. This indent can be used by the sampling team while making samples and by QC to check the sample.

Challenges faced during sampling which results in delay in sample or rejection (internal or external) of sample:

- Not having adequate information from customers for sample development like construction details, fabric/ trims confusion, etc.

- Poor communication between merchant and sampling team which results in rework.

- Unavailability of raw materials like labels, buttons during sampling.

- No or less clarity to sampling QC on the requirement of the customer in terms of quality parameters (especially, in case of new buyer).

- Less understanding of buyers tech pack to sampling operators.

- Rejection of sample after making due to fabric issue (like fabric defects or shade present).

The following measures can be incorporated so as to eliminate above mentioned challenges during sampling:

1. Complete clarity of sample needs to be developed

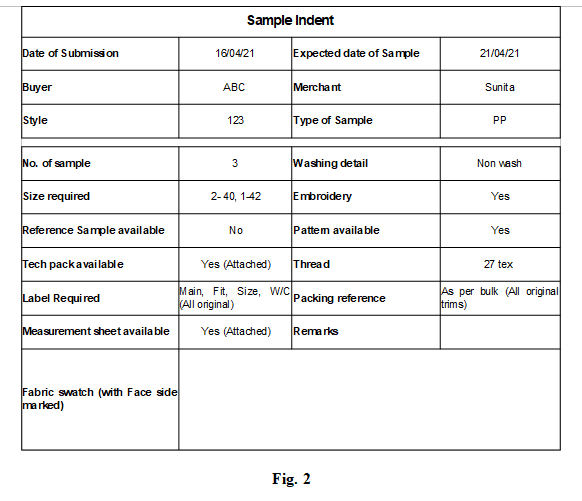

Before handing over the sample request to the sampling, a merchant needs to take complete clarity from the customer about the sample. This should be done during proto/fit sampling as 80% of things are closed at this stage. Merchant can make a checklist to ensure he/ she has all the required information about the sample. An example of a checklist is shown in the following figure (Fig-1).This sheet will help to collect all required information from customers in one go. Either we can send this to the customer to fill or we can collect information from him through mail or call. This checklist can be updated at regular intervals as per requirement.

2. Making a sample indent having all information about the sample

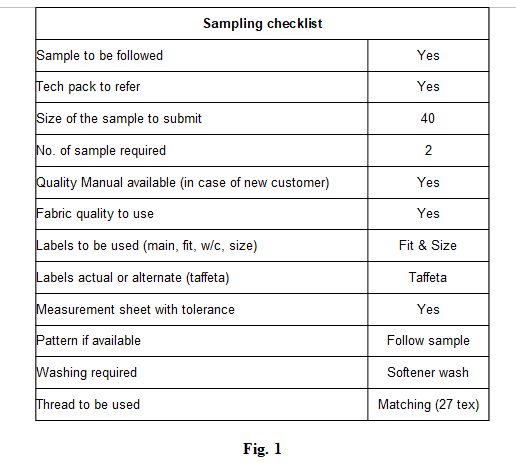

Poor communication between the merchant and sampling is the biggest reason for sample failure and delay in submission. Many times a merchant verbally informs the sampling department about the sample and there are no proper records of the verbal communications. Due to this there will be too much to and fro between the sampling, QC and merchant which results in delay or rejection. If everything is not properly communicated there are chances of things missing out and rejection from customers resulting in re-submission. Based on the above sampling checklist, merchants can prepare a sample indent containing all information and submitting to sampling. An example of same is shown in the Figure-2.It will eliminate any chances of error which can cause any issue. This indent can be used by the sampling team while making samples and by QC to check the sample.

3. Making a complete package of fabric and trims while handing over to sampling

Sometimes few things are forgotten and not handed over at times. This will result in hampering work due to unavailability of material. For example, buttons are missed to give. Now the sample is ready but can't be dispatched due to buttons pending. This will cause delay in sampling. So merchants should make a complete package of all the trims and fabric and hand it over to sampling at once. If anything is missing then it needs to be informed at the time of giving sampling indent. Sampling department should check all the material while taking the indent from a merchant. This will save a lot of time and result in faster sample delivery.4. Making a internal tech pack for easy reference for operator and checker

Many times the buyer’s tech pack is not easy to understand by the quality checker or sewing operator or even by the supervisor. Also each buyer will have a different format of tech pack. This can result in misunderstanding of technical details. To avoid this problem we can make an easy to understand tech pack with a common format so that operator and checker can read and understand easily. This can be made by QA by hand or by CAD software with diagrams. This will help to get clear and fast information like type of seams, basic measurements like height, width, placements of labels and buttons, etc. This will help operators in making samples as per requirement without any confusions. The checker can also use the same reference to check the samples. Also these sheets can be used in sewing during bulk production of the same order.5. Sample rejection after making due to fabric and trim issues

We all have faced these issues many times in our life. After the sample is fully made then some shade problem is seen may be due to CSV present in fabric, or fabric defects, or excessive shrinkage in fabric or labels or tapes used. We always check the fabric and trims for bulk production on multiple parameters but fail to check the fabric given to sampling. Samples are generally made from the yardage received from supplier or customer and directly handed over to sampling for sample development without checking. There could be any problem present in the yardage which will bypass and result in sample rejection. So always fabric yardages and trims should be checked for defects, shade, and shrinkage. If any problem found counter measures needs to be taken or should be highlighted to the customer in advance. No one wants to reject the sample after making it due to basic fabric issues.Conclusion:

Following above measures will help to eliminate causes of sample delay or sample rejection which will improve our working. If sampling activities take place on time without any failure or resubmission then orders can be delivered at a faster rate. It will also boost customer satisfaction and improve factory performance.About the Author

Shobhit Jindal is a graduate from NIFT with a degree in apparel production. He has done his MBA from Amity University in Operations. He has a total experience of years in apparel industry in field of industrial engineering, Quality control and Audit, Production and Product Development.