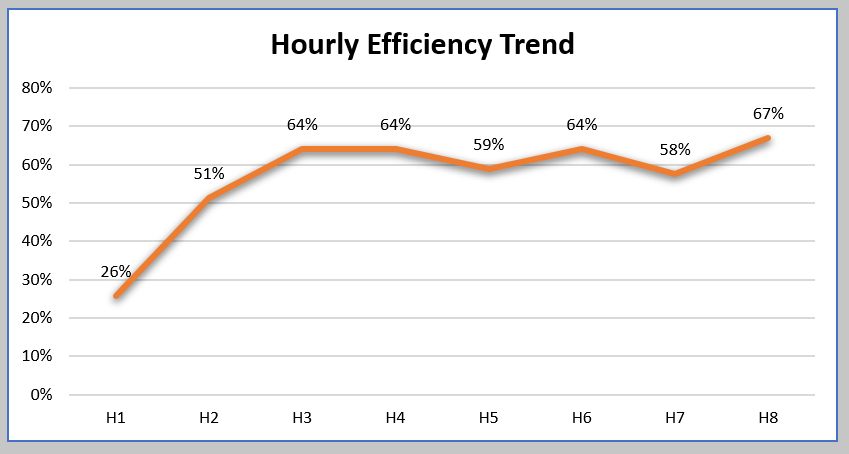

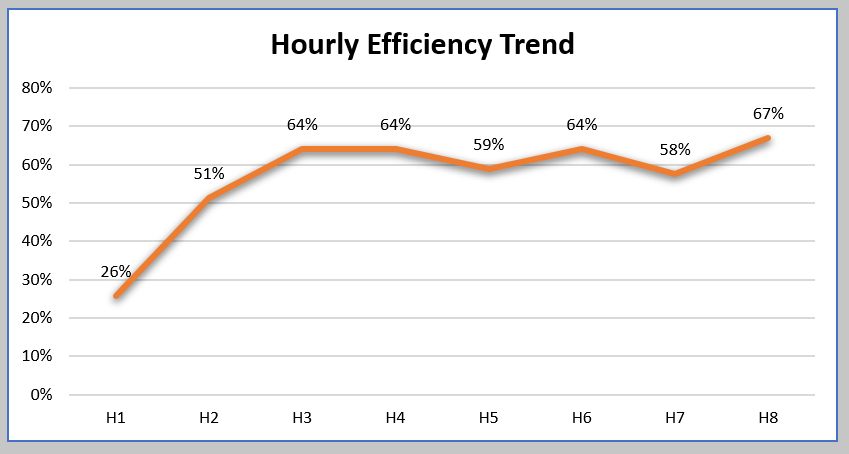

There are many ways one can see the factory's performance. When it comes to controlling a production line, real-time data has a big impact. Hourly production data, daily line output and daily efficiency data are some of those. Hourly production report display is common in garment factories. In this post, I will show you how to prepare the hourly efficiency of a production line. Through the hourly efficiency data, you can see the trend and pattern of the efficiency curve.

Normally, in garment factories line output data is recorded in hourly intervals and displayed on a display board on the wall in front of the production line. Some engineers keep hourly production records on their computers. By doing so, they can do further analysis of the previous day’s hourly production and backtrack production data when needed.

Regarding efficiency calculation, line efficiency is calculated on a daily basis. Most of the garment manufacturers get the line efficiency data the next morning. However, with the aid of the latest tech solution, some factories can see their line performance data on the same day. In the current day, they see line efficiency for all working hours from the factory start time to the current time (now).

There are some engineers, who like to see data in a different way. Some aim to control the line and controlling production. Through a closer analysis of the line performance and employee performance, they can control the production of a line in a better way. An in-depth analysis will give factories act proactively. We have understood that in the initial hours of the day, line output (production) will be low. If we hourly report data of a factory for the one-month duration, it will clearly show you the fact. We have posted an article on this topic.

Related post: How to Improve First-Hour Production in a Garment Factory?

Calculate hourly line efficiency from the line output data. It would be easier to get the efficiency trend of each production from morning to evening (from starting the shift to the end of the shift).

You can prepare this hourly efficiency trend whether a line is working on a single style or multiple styles in a day. Here is the data set you need to collect.

During the day, the operator’s headcount may change. So, if you want to calculate working hours based on the actual attendance, you can do that.

In the template, pre-calculate the total produced minutes by the hour using the formula

Produced minutes = (Produced quantity x style SAM)

Calculate minutes attended by operators and helpers.

Normally, in garment factories line output data is recorded in hourly intervals and displayed on a display board on the wall in front of the production line. Some engineers keep hourly production records on their computers. By doing so, they can do further analysis of the previous day’s hourly production and backtrack production data when needed.

Regarding efficiency calculation, line efficiency is calculated on a daily basis. Most of the garment manufacturers get the line efficiency data the next morning. However, with the aid of the latest tech solution, some factories can see their line performance data on the same day. In the current day, they see line efficiency for all working hours from the factory start time to the current time (now).

There are some engineers, who like to see data in a different way. Some aim to control the line and controlling production. Through a closer analysis of the line performance and employee performance, they can control the production of a line in a better way. An in-depth analysis will give factories act proactively. We have understood that in the initial hours of the day, line output (production) will be low. If we hourly report data of a factory for the one-month duration, it will clearly show you the fact. We have posted an article on this topic.

Related post: How to Improve First-Hour Production in a Garment Factory?

How to calculate the hourly efficiency of a production line and the individual operators?

From the hourly production data, we can prepare this report. In case you are not capturing the hourly output of your production, you need to initiate that first. Once you have it, follow the below steps to get the pattern of hour-by-hour efficiency up and down in a day.Calculate hourly line efficiency from the line output data. It would be easier to get the efficiency trend of each production from morning to evening (from starting the shift to the end of the shift).

You can prepare this hourly efficiency trend whether a line is working on a single style or multiple styles in a day. Here is the data set you need to collect.

- Hourly production qty

- Style SAM

- Manpower

- Production date,

- Line number,

- Supervisor’s name,

- Break up of operators and helpers in total manpower,

- Number of machines and

- style number

During the day, the operator’s headcount may change. So, if you want to calculate working hours based on the actual attendance, you can do that.

Step-1: Prepare a template

Prepare an Excel template for capturing hourly production data, total manpower works in a line. For detailed analysis, you can include information line, date, line number, style number, Style SAM, etc. See the below image for the reference template.In the template, pre-calculate the total produced minutes by the hour using the formula

Produced minutes = (Produced quantity x style SAM)

Calculate minutes attended by operators and helpers.

Minutes worked = (Manpower x 60 minutes)

In example-1, I have shown calculation when a line works in a single style for the whole day. In the second example, hourly efficiency calculation is shown for two styles. For multiple styles, you need to combine produced SAM for all styles by the hour.

In the above template, H1, H2, and H3 are hours breakup. H1= First hour of working, H2 shows second hour of working.

Do you want to calculate hourly efficiency for individual employees working in your line?

You can do that by following the above steps. For this, you need to consider individual employees’ hourly production quantity for the specific operation they are working on and operation SAM.

Step-2: Collect data.

Once you have production collect data from the line output. Enter the hourly production data in the excel template. Once enter the hour production, you will get the calculated data in the other three rows – Produced minutes, Minutes worked, and hourly efficiency.In example-1, I have shown calculation when a line works in a single style for the whole day. In the second example, hourly efficiency calculation is shown for two styles. For multiple styles, you need to combine produced SAM for all styles by the hour.

In the above template, H1, H2, and H3 are hours breakup. H1= First hour of working, H2 shows second hour of working.

Step 3: Prepare a chart for the efficiency trend

In the Excel template, add a chart for viewing hourly efficiency by date. An example of such

Do you want to calculate hourly efficiency for individual employees working in your line?

You can do that by following the above steps. For this, you need to consider individual employees’ hourly production quantity for the specific operation they are working on and operation SAM.