In this post, I will be showing you a different format for production reporting used by an MTM suit manufacturing factory.

In a single day, the factory works on more than 50 different orders. The WIP pieces of each order lie in different stages. So looking into daily production reports by each order separately would be overwhelming. The production manager and data analyst need to see the production summary at 7-10 key production stages by date. Also, the production manager and company CEO prefer to view production data by product categories.

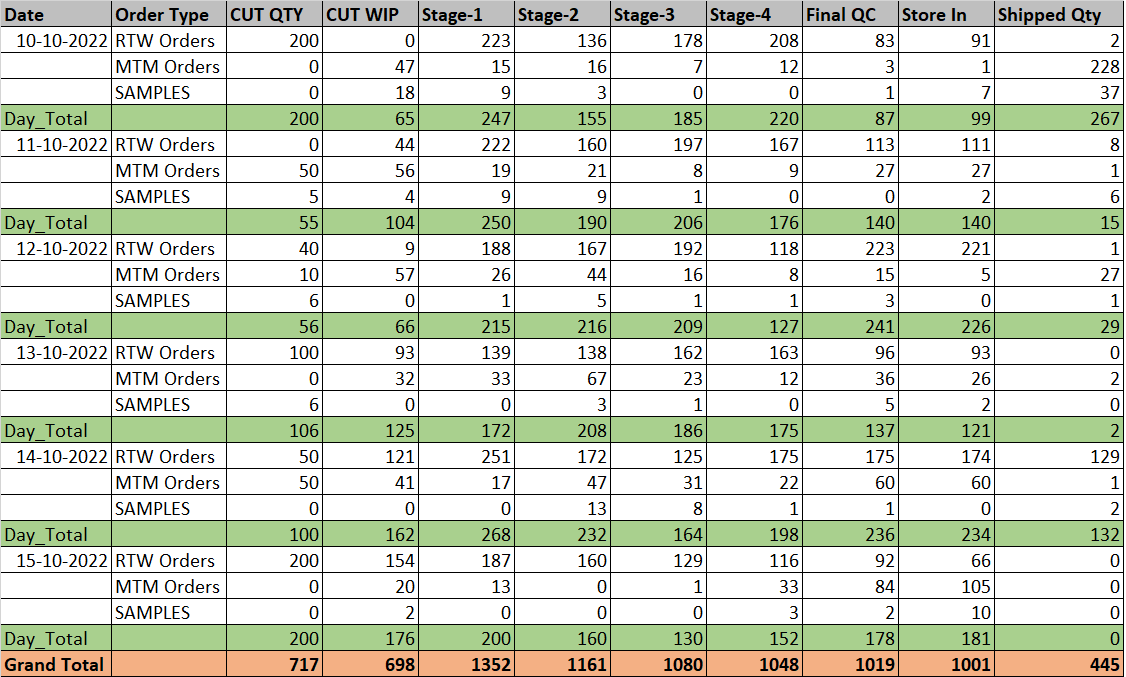

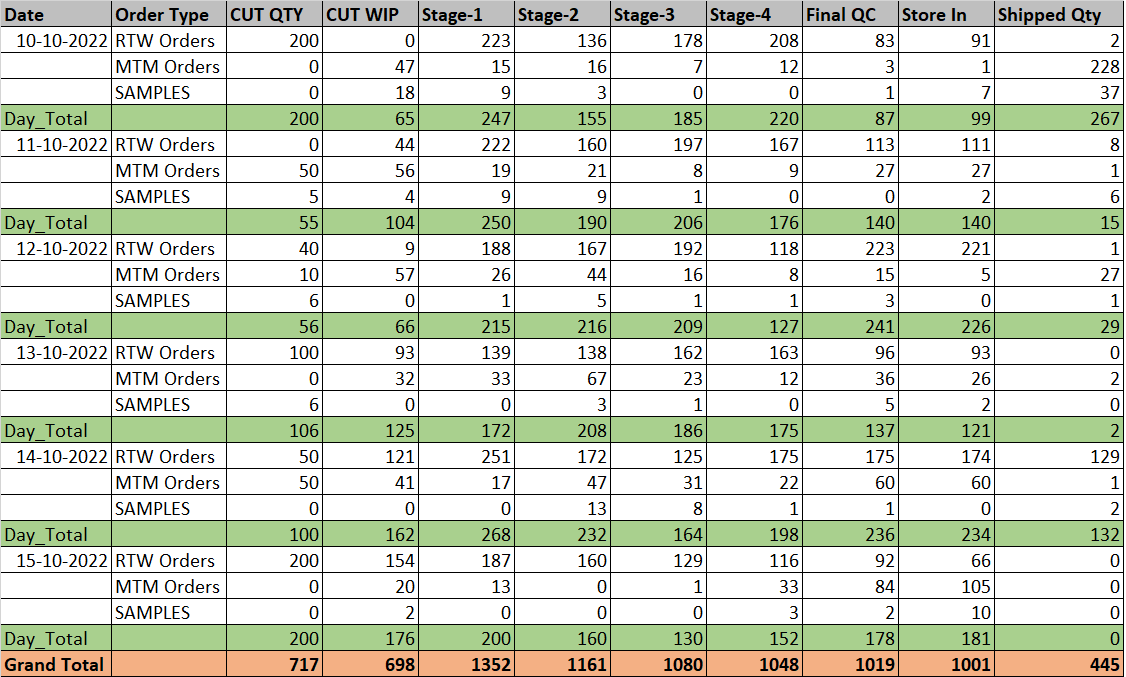

Image#1. Report summary for multiple days (here one calendar week)

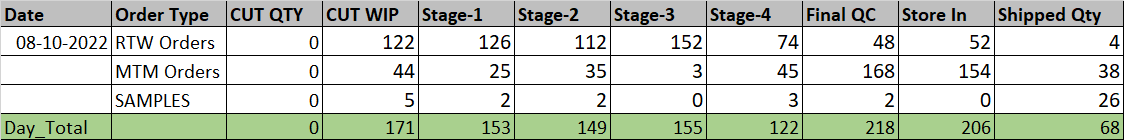

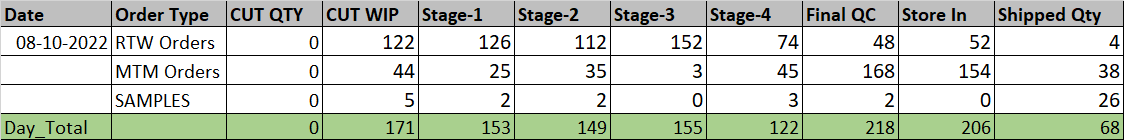

Image#2. Report summary for a single date

What is new in this daily production report format?

In most cases, daily production reports are made on daily basis and the report is read and discussed on the same day. But in this report, you can see production data for the week or a month on a single page by filter date range.

This report is a summary of all orders by grouping production quantity into product categories. Here the production quantity is reported from different production stages.

Another good thing about this report format - we normally see production data at the sewing line output and final finishing stage. They track production data in 5-6 stages (specific operations) in production and additionally see other production and finishing stages as shown in the following report template.

Another good thing about this report format - we normally see production data at the sewing line output and final finishing stage. They track production data in 5-6 stages (specific operations) in production and additionally see other production and finishing stages as shown in the following report template.

Real-life example

This report is used by a suit manufacturer. The company manufactures ready-to-wear (RTW) suits, Made-to-measure (MTM) suits, and suit samples for their buyers.

These different types of product combinations in an order are received for single-piece orders or sometimes they are used to get bulk orders with the above combination. If you look into the production floor of this suit manufacturing factory, you will be surprised to know the number of sewing operations and associated non-sewing operations after the cutting process. Secondly, different types of sewing machines (including automatic, and semi-automatic) are used for making suits from cutting to finished suits.

- A suit order normally contains two-piece of suit - one jacket and one pair of trousers.

- A suit order may contain three-piece suits - one jacket and two trousers

- A suit order may contain three-piece suits - one jacket, one vest, and one trousers

In a single day, the factory works on more than 50 different orders. The WIP pieces of each order lie in different stages. So looking into daily production reports by each order separately would be overwhelming. The production manager and data analyst need to see the production summary at 7-10 key production stages by date. Also, the production manager and company CEO prefer to view production data by product categories.

Report Format

The report format is shared here. In the format, stage-1 to stage-4 refers to the preparation parts of the suit and trousers before jacket assembly starts. Preparation of jacket shell and lining. You can include more production stages if you need to see and analyze such production data.The format first shows the production quantity by date for each product type and then it calculates the day's total quantity. This repeats for each date. Data is available in an Excel file and the user can select the date(s) for which he/she wants to view the production summary. At the end (when multiple dates are selected), it shows the grand total of all dates (image 1).

Image#1. Report summary for multiple days (here one calendar week)

Image#2. Report summary for a single date

Note:

Tracking production of all operations (for jackets and trousers) would be too much work for the report preparation guy. This factory uses a shop floor control system to capture and track stage-wise production data in real-time. The shop floor control system helps them easily get all kinds of production and WIP reports.