We know fashion manufacturing is a challenging process for many reasons. Trim sourcing and getting quality trims for bulk orders is one such challenging task for apparel manufacturers. Another essential point in order execution is sourcing each trim in the right quantity as per order volume. Garment manufacturers normally use an average consumption of each item for purchasing trims for the whole order. For smooth production running in bulk production, garment manufacturing businesses need to follow the standard procedure (SOP) for estimating trims average and calculating final requirement of trims. (Trim shortage will cause delay in completing whole order and excess trim purchase will incur extra cost in trims or waste of materials).

It is obvious that different apparel products are made of different types of trims. Sewing thread is one such common trim which is essential for sewing garments. To explain the SOP for calculating trim average, we will take sewing thread for an example. You can develop similar SOP for estimating average and procuring other trims.

When you receive a style file for the upcoming style, you must check the trim average sheet (Trim card) and thread order sheet in the file. You may see two situations as follows.

(A) Trim average sheet is available in the file. In such a situation you must check all trims calculation average provided as per received sample (approved sample). If you find trim card with sample average, it is okay for move forward. If you don’t find the correct sample average, then ask the changes. The best way of handling this is initiating e-mail communication with concerned person in the company. Share your findings like average is increase/decrease with the concerned person.

(B) In case trim average sheet is not available in the style file, demand for it from the merchant. Alternatively, you can take printout of the same from the production manager. Or collect the trim sheet from trims store. After collecting the data, follow the same work process mentioned in "A".

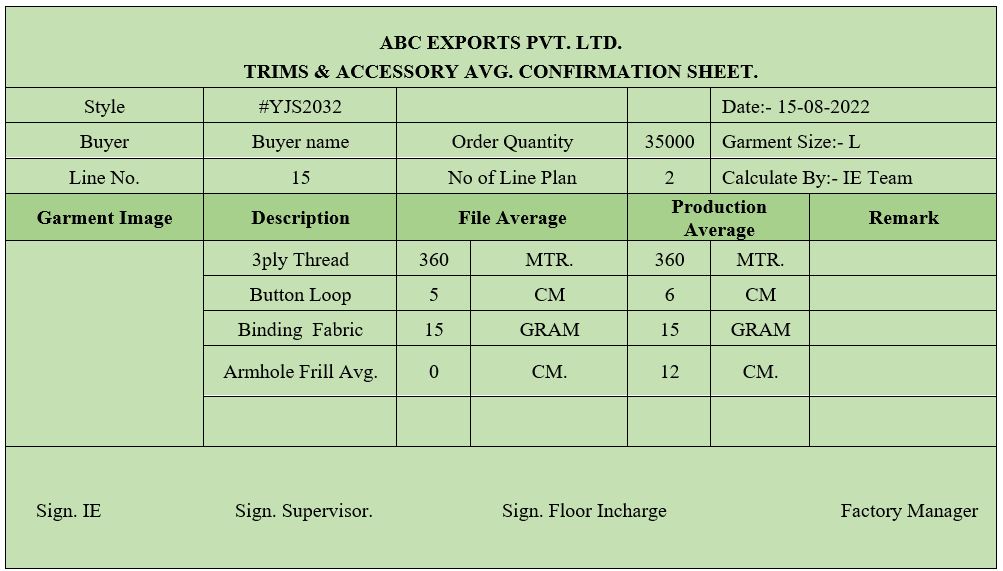

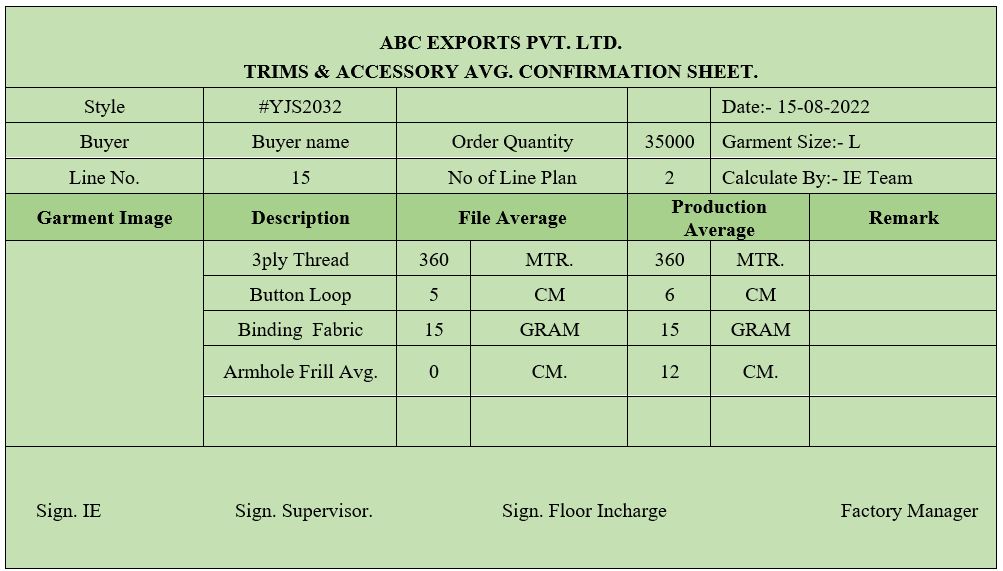

Image: Trims average confirmation sheet

2. Calculate bulk average

During garment sampling process, calculate bulk average for all kind of trims which will consume in production like thread, elastic, tapes, zipper, laces, lining, fusing etc.

2. Mention the style details in the format (Style file). Follow the techpack for style detailing.

3. Take all the operations from the operation bulletin (OB) and paste it in the format. For this step, you must have the ready operation bulletin for the selected style.

4. Measure seam length of the garment from the 1st operation. This is essential for calculating thread average.

5. Seam length to be taken from edge to edge of the seam.

6. Seam allowance is added into the thread calculator. You can use this thread average calculation Excel template.

7. If any operation is missed while doing the initial average, the missing operation(s) must be added in production.

8. After completing all the operations, re-check the machines used for each operation, to avoid any errors in calculating with thread factor.

9. Using thread calculator, you get thread average for the selected style. This average is then used for total thread requirement calculation and used in the bill of material sheet.

After completing thread average calculation, calculate the other trims average one by one and mention it in the format.

Different trims have different measuring units and ways of measuring average. Follow the right method and estimate average consumption per garment. Like labels are counted in units. Lining material is measured in area and converted to linear meter based on lining fabric width.

10. Do verify the values entered in the trim sheet, and then send the emails to the concerned person.

11. Once confirmed, save it as a PDF file, and take print it and make sign off by PM/FM/FI respective formats.

12. After getting a signature from an authorized person, scan the signed document and forward the same to the concerned merchant and concerned departments by email.

13. During making the bulk production, I.E and the production department must be careful of trim wastage in manufacturing processes. Operator and workers should not make more wastage as per the added allowances.

Regarding thread calculation templates, trims average confirmation formats, you can design it by your own or use the attached sample templates.

More articles by Babul Singh

How to remove iron rust from sewing machine parts?

How to manage sharp tools in a garment factory?

Know why sewing operators leave their first company after getting operator training

It is obvious that different apparel products are made of different types of trims. Sewing thread is one such common trim which is essential for sewing garments. To explain the SOP for calculating trim average, we will take sewing thread for an example. You can develop similar SOP for estimating average and procuring other trims.

Standard operating procedure (SOP)

1. Check the file average

When you receive a style file for the upcoming style, you must check the trim average sheet (Trim card) and thread order sheet in the file. You may see two situations as follows.

(A) Trim average sheet is available in the file. In such a situation you must check all trims calculation average provided as per received sample (approved sample). If you find trim card with sample average, it is okay for move forward. If you don’t find the correct sample average, then ask the changes. The best way of handling this is initiating e-mail communication with concerned person in the company. Share your findings like average is increase/decrease with the concerned person.

(B) In case trim average sheet is not available in the style file, demand for it from the merchant. Alternatively, you can take printout of the same from the production manager. Or collect the trim sheet from trims store. After collecting the data, follow the same work process mentioned in "A".

Image: Trims average confirmation sheet

2. Calculate bulk average

During garment sampling process, calculate bulk average for all kind of trims which will consume in production like thread, elastic, tapes, zipper, laces, lining, fusing etc.

SOP for calculating trims average for bulk production

1. Select the base size of the style for average consumption calculation. For example, if the order has a size range of Small, Medium, Large, XL and XXL, you can take garment of ‘Medium’ size for calculation.

2. Mention the style details in the format (Style file). Follow the techpack for style detailing.

3. Take all the operations from the operation bulletin (OB) and paste it in the format. For this step, you must have the ready operation bulletin for the selected style.

4. Measure seam length of the garment from the 1st operation. This is essential for calculating thread average.

5. Seam length to be taken from edge to edge of the seam.

6. Seam allowance is added into the thread calculator. You can use this thread average calculation Excel template.

7. If any operation is missed while doing the initial average, the missing operation(s) must be added in production.

8. After completing all the operations, re-check the machines used for each operation, to avoid any errors in calculating with thread factor.

9. Using thread calculator, you get thread average for the selected style. This average is then used for total thread requirement calculation and used in the bill of material sheet.

After completing thread average calculation, calculate the other trims average one by one and mention it in the format.

Different trims have different measuring units and ways of measuring average. Follow the right method and estimate average consumption per garment. Like labels are counted in units. Lining material is measured in area and converted to linear meter based on lining fabric width.

10. Do verify the values entered in the trim sheet, and then send the emails to the concerned person.

11. Once confirmed, save it as a PDF file, and take print it and make sign off by PM/FM/FI respective formats.

12. After getting a signature from an authorized person, scan the signed document and forward the same to the concerned merchant and concerned departments by email.

13. During making the bulk production, I.E and the production department must be careful of trim wastage in manufacturing processes. Operator and workers should not make more wastage as per the added allowances.

Conclusion:

By following above steps for trims average checking and confirmation from concerned person, you can avoid last minute surprise of trim quality mismatch issue for a running order.Regarding thread calculation templates, trims average confirmation formats, you can design it by your own or use the attached sample templates.

More articles by Babul Singh

How to remove iron rust from sewing machine parts?

How to manage sharp tools in a garment factory?

Know why sewing operators leave their first company after getting operator training