1. What is a production progress report?

The production report that is prepared to view the production advances across the major production stages is called a production progress report. The purpose of making this progress report is to view the so-far production quantity of the selected processes (operations) and inventory level across the processes.In this report, only the major processes are considered to show the production progress of the running orders. One can also see the progress report of the orders that are already shipped in the past months.

Like the daily production report (DPR), the progress report is prepared by garment manufacturers on a daily basis. In the daily production report, the major focus remains on viewing the production volume of the last production day and cumulative production. On the other hand, a production progress report focuses on the progress status of orders in terms of volume across the processes.

This report is important for managers to run the business smoothly. By having production progress data, you can view the order status by production stages. You can project the possible date when the order will be ready for shipment. You can update your customers on the current production status.

In this article, I will talk about the production progress report in the garment manufacturing sector.

Second, you need to identify the major processes for which you want to know the number of units produced so far by order number. You can see so far production data by color and by garment size.

The selection of major processes depends on the product type you are making in your company and the production system that you are following for manufacturing apparel items.

Let’s say you are making shirts in assembly lines. You have different sections for cutting, stitching, and shirt finishing. In such cases, the few key processes could be as the following

And you also want to know how many pieces are waiting as a WIP on the key processes.

So, you can also include some key processes of the sewing operations. In case the product has more than 50 sewing operations and the production throughput time is more than 2-3 days, you may need to track production advances in the key stitching operations or at the garment parts completion stages.

For example, in the case of suit items, factories are used to track production advances for parts like, sleep ready, front part ready, back part ready, Jacket lining ready, assembly production start, assembly complete, and finishing ready to ship quantity.

These are just an example of the key processes. In your factory, identify the key processes in the production. Then capture produced garments on a daily basis and use that daily data in making this report. In the following section, I will show you the report template.

The Excel report template shared below is self-explanatory. You can prepare the same template in an Excel spreadsheet and collect the data for preparing a production progress report.

Do you have data for daily production records?

If so, you can pull the production data by process (production stage) and display it on this progress report. You can utilize that data in order to make the progress report.

In case, you don’t have the daily record, you can start capturing daily production records from those specific sections.

You can visualize the WIP level in each stage.

Improve visibility of order across the production processes

You can see where the whole pieces of any order are spread over. See Figure-2.

Related Reports:

In this article, I will talk about the production progress report in the garment manufacturing sector.

2. How to make a progress report?

To make the production progress report, you need the production data of the selected processes. For the data source, one can use the DPR records. The common report we see garment factories used to make on a daily basis is the daily production report (DPR).Second, you need to identify the major processes for which you want to know the number of units produced so far by order number. You can see so far production data by color and by garment size.

The selection of major processes depends on the product type you are making in your company and the production system that you are following for manufacturing apparel items.

Let’s say you are making shirts in assembly lines. You have different sections for cutting, stitching, and shirt finishing. In such cases, the few key processes could be as the following

- Cutting process,

- Stitching process,

- Quality-checked units,

- Garment Ironing and

- Packed garment quantity.

And you also want to know how many pieces are waiting as a WIP on the key processes.

So, you can also include some key processes of the sewing operations. In case the product has more than 50 sewing operations and the production throughput time is more than 2-3 days, you may need to track production advances in the key stitching operations or at the garment parts completion stages.

For example, in the case of suit items, factories are used to track production advances for parts like, sleep ready, front part ready, back part ready, Jacket lining ready, assembly production start, assembly complete, and finishing ready to ship quantity.

These are just an example of the key processes. In your factory, identify the key processes in the production. Then capture produced garments on a daily basis and use that daily data in making this report. In the following section, I will show you the report template.

3. Sample template of a progress report

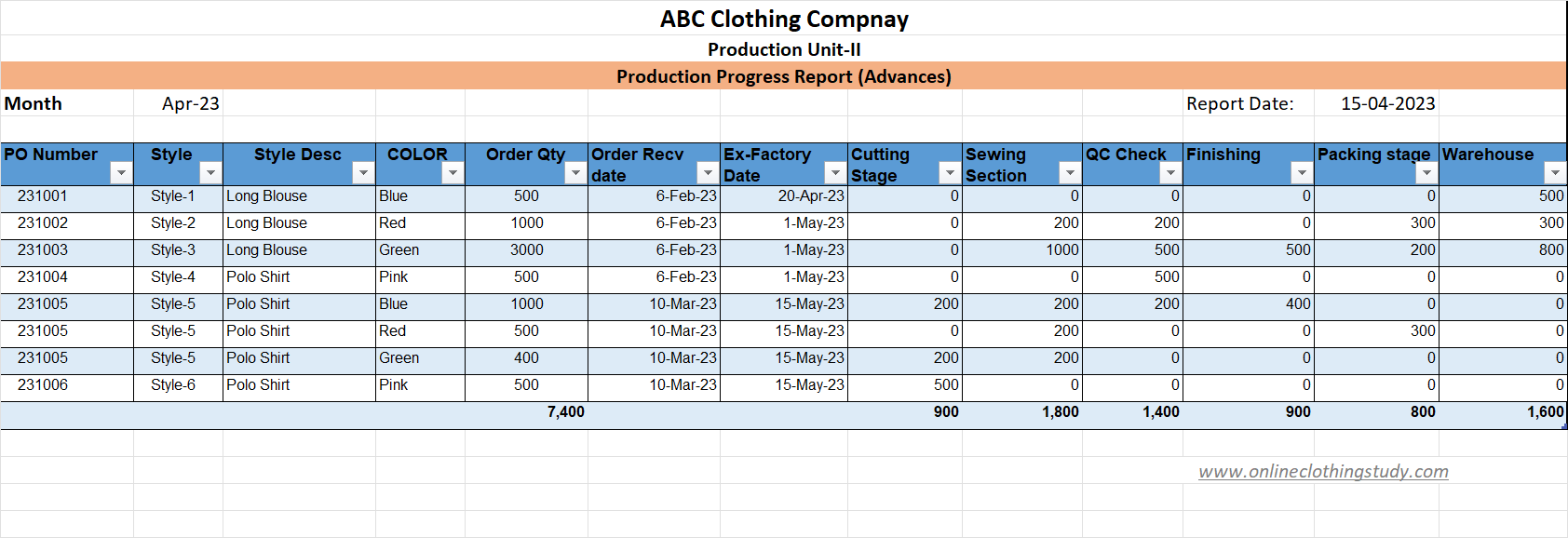

I will use an Excel spreadsheet to explain this part.The Excel report template shared below is self-explanatory. You can prepare the same template in an Excel spreadsheet and collect the data for preparing a production progress report.

Figure-1: Production progress report (showing so far produced quantity at selected processes)

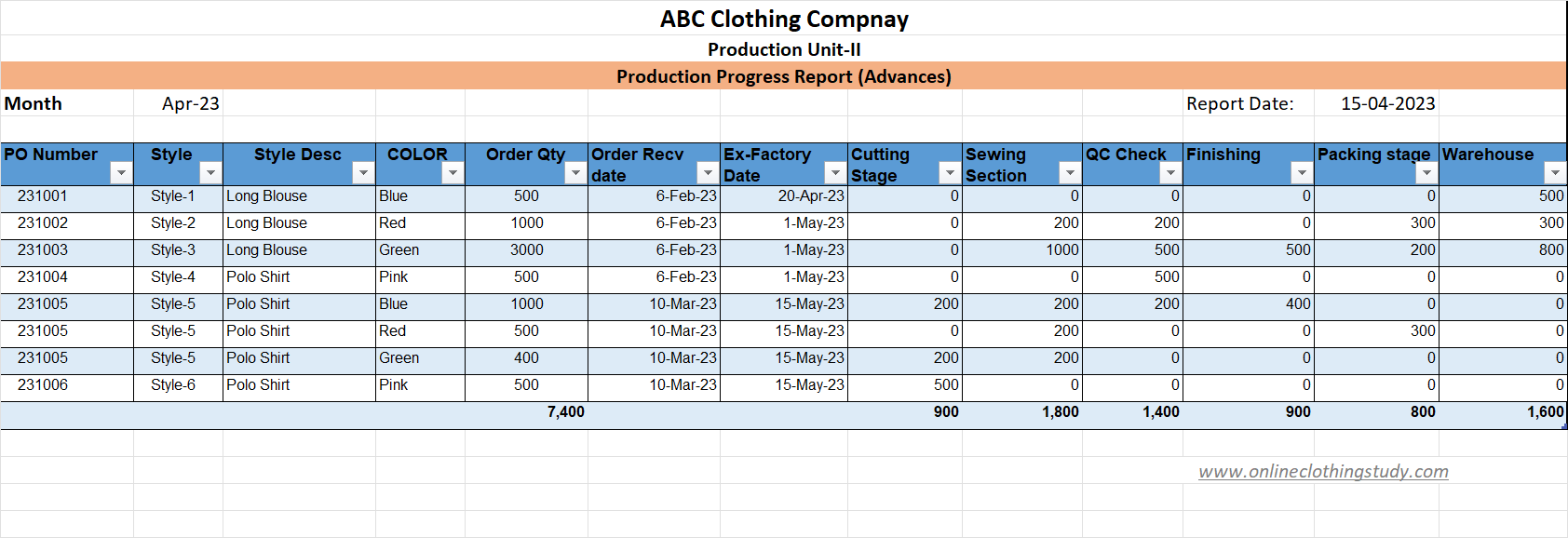

Figure-2: Production Advances report (showing inventory volume at selected processes)

Do you have data for daily production records?

If so, you can pull the production data by process (production stage) and display it on this progress report. You can utilize that data in order to make the progress report.

In case, you don’t have the daily record, you can start capturing daily production records from those specific sections.

4. Benefits of Production Progress Report

In Figure-1, you see the so-far produced quantity in five major processes. You can compare the production volume in each stage with the order quantity. Or compare the actually produced quantity against the cut quantity.You can visualize the WIP level in each stage.

Improve visibility of order across the production processes

Helps production managers in controlling and managing the production floor

You can see where the whole pieces of any order are spread over. See Figure-2.

Let’s take an example of style-2 in the second format. Order quantity 1000 pieces.

You have cut fabrics for all 1000 pieces, so no work is pending at the cutting stage. Cuttings are loaded to the sewing stage and work has been moved to further processes. You can see how 100 units of garments spread over different stages.

- Cutting stage - 0 units

- Sewing stage - 200 units

- QC stage - 200 units

- Finishing stage- 0 units

- Packing stage - 300 units

- Warehouse - 300 units

This report will show you the inventory level at each stage.

Related Reports: