Contributor: Aayushi Kumar

The modes of marker making and spreading are essential concepts in apparel mass production, where garment symmetry and fabric symmetry affect the selection of marker modes as well as the methods of spreading and cutting. These factors affect the cost of the product as well.

To define marker making and spread modes, we use specific definitions of fabric and garment symmetry. There are two types of fabrics classified based on their visual appearance-

Related: What is Splicing in fabric spreading?

Nap one way - As the name suggests, the nap is in the same direction implying that this spreading mode is for asymmetric and unidirectional fabrics. (Refer to example 1)

Nap either way- As the name suggests, the nap can be in any direction which means that this type of spreading mode is ideal for symmetric fabrics that do not change their appearance despite 180° rotation in the same plane. (Refer to example 3)

Now, the fabric face (while placing different layers on top of each other) may be positioned in two ways-

1) Face one way (F/O/W) - Which means, all plies facing in the same direction (either upward or downward)

2)Face-to-face (F/F) - This means, the face side of one layer is placed against the face side of another fabric layer.

Overall, we can now say that for any fabric there are the following possibilities in which they can be spread-

1. Nap one way, face one way (NOW, FOW)

It is the most common spreading method. As the name suggests, the nap is in one direction which means, it is a good alternative for an asymmetric fabric. Since the face side shall be in one specific direction, symmetric fabrics can be cut as well.

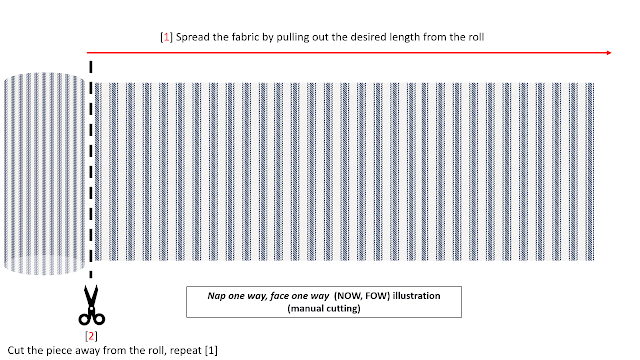

Manual spreading- The fabric roll is kept on a stationary roller stand and the fabric end is pulled by two spreading operators unwinding fabric from the freely rotating roll. Here fabric roll remains stationary. Visualize this scenario by looking at the illustration below-

Machine spreading- The loose end of the fabric is held by the catcher and the machine carries the rolls along the table length thus unwinding and spreading the fabric in the process. Every layer has to start from the same end thus spreading machine has to come back to the starting position without spreading the fabric. This return movement of the spreading machine is called “deadheading”. Check out the illustration below-

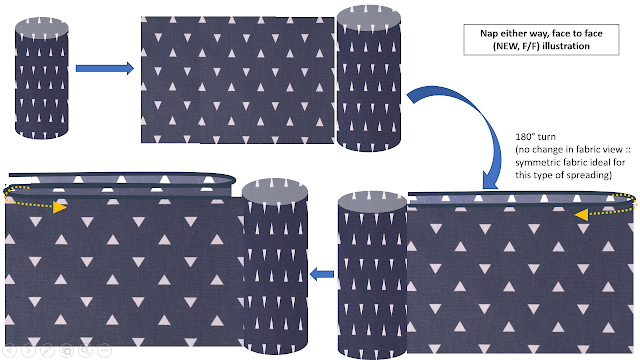

2. Nap either way, face to face (NEW, F/F)

It is the quickest spreading method when done using a spreading machine. However, it is difficult to accomplish manually. Remember, when deciding what type of fabric can be spread for the given spreading mode, one must consider the nap direction as well as the face of the fabric . Therefore, if you observe, the nap of the fabric will not change for both symmetric and asymmetric fabric.(Imagine the elephant printed fabric, you will realize that the foot of the mammal shall be towards the floor if it is spread in this spreading mode)

The machine carries the fabric roll while the end is being held in place by the catcher. The end of the fabric layer is not cut, it is folded and held by another catcher while the fabric is being laid by the machine during its return movement as well. Refer to the illustration below-

3. Nap one way, face to face (NOW, F/F)

Nap one-way, F/F is the most time-consuming method of spreading. Since the two similar faces of the fabric shall be placed against each other, it must be symmetric so that the look of the fabric does not change on 180° rotation.

The loose end of the fabric is held by the catcher and the machine carries the rolls along the table length while unwinding and spreading the fabric in the process. The fabric is cut at the end of the layer and the turntable rotates the fabric roll by 180 degrees. Meanwhile, the roll returns to the starting position without spreading (i.e. deadheading). The roll again spreads the second layer of the fabric face to face, and the process repeats.

To understand better, refer to the figure below which shows how the fabric shall be spread-

The figure below demonstrates how a piece of the pattern, when traced and cut out of this type of spreading mode shall look like-

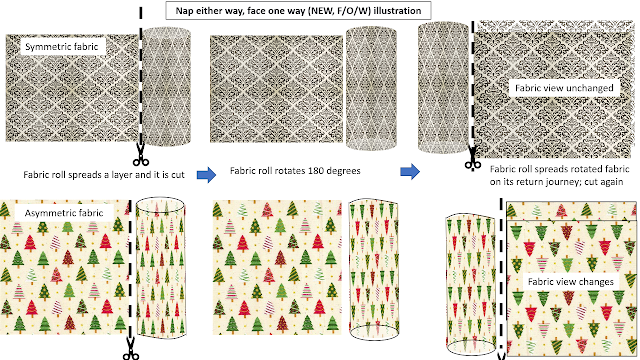

4. Nap either way, face one way (NEW, F/O/W)

The loose end of the fabric is held by the catcher and the machine carries the rolls along the desired table length while unwinding and spreading the fabric in a process similar to the previous method. The fabric is cut at the end of the layer and the turntable rotates the fabric roll by 180 degrees. Meanwhile, the roll returns to the starting position spreading the fabric. The fabric is cut, roll rotates again, and then spreads the second layer of the fabric, and the process repeats. This type of spreading mode is ideal for symmetric fabrics. By doing so, despite the face of the fabric is spread in one direction, and the nap direction changes with each spread, the appearance of the fabric will not change. To understand this, look at the illustration below-

Imagine a piece of bodice pattern traced on top of each of the cases illustrated above. When cut out, for symmetric fabric, two parts shall come out identical. Meanwhile, for asymmetric fabric, one piece shall come out fine while the other will be tops turvy!

Related post: Cutting room terminologies

To define marker making and spread modes, we use specific definitions of fabric and garment symmetry. There are two types of fabrics classified based on their visual appearance-

A) Symmetric Fabrics

No change in appearance when the fabric is turned 180 degrees in the same plane. In most cases, fabric symmetry is concerned with only the face side and the back is of minimal concern, as it shall be inside the garment and out of the view. Solid colour plain weave fabrics are often symmetric.

Example -1: Direction of Nap

To decide the direction of the nap of the fabric, consider the elephant printed fabric shown in the example below, where all the legs point in the same direction i.e. downwards. Naturally, in a garment, these would point toward your toes. One would not usually prefer an elephant to be standing on their heads! Hence, the nap direction is obvious in this case.

Example 2: Nap decides asymmetry or symmetry of the fabric

The triangular printed fabric is pointing towards a specific (upward) direction or "nap", it means that the fabric is asymmetric.

Those fabrics having no visible nap direction are symmetric as explained in the example below-

In the case of knit fabrics, the structure of the fabric changes on rotation by 180°, which means they are asymmetric. However, there are instances where the nap direction of the knitted fabric does not matter. In the case of Jersey knit - having small loops, and smooth fabric texture permits an acceptable appearance in either direction.

Fabrics with surface fibres such as velvet are asymmetric. When mills prepare rolled piece goods, the "down direction” is usually toward the open end of the roll. And it is the same direction that the open ends of the fibres naturally point. Since velvet is made in rolled piece good form, it means that it has a distinct unidirectional nap, which implies it is asymmetric.

(B) Asymmetric Fabrics

If there is a change in appearance when the fabric is turned 180 degrees in the same plane then the fabric is said to be asymmetric. Even if a fabric when rotated at 180 degrees, causes a change in colour due to light reflection is asymmetric. Refer to the illustration below-Understanding fabric nap directions

The surface directionality or the view of the fabric is called a nap. Or if the fabric has surface fibres /short threads (like velvet, corduroy, etc), the direction that they naturally lay is the nap of the fabric. A nap of the fabric is created by its structure, a finish, or a directional print. Let us now understand the concept of naps with few examples-Example -1: Direction of Nap

To decide the direction of the nap of the fabric, consider the elephant printed fabric shown in the example below, where all the legs point in the same direction i.e. downwards. Naturally, in a garment, these would point toward your toes. One would not usually prefer an elephant to be standing on their heads! Hence, the nap direction is obvious in this case.

Example 2: Nap decides asymmetry or symmetry of the fabric

The triangular printed fabric is pointing towards a specific (upward) direction or "nap", it means that the fabric is asymmetric.

Those fabrics having no visible nap direction are symmetric as explained in the example below-

In the case of knit fabrics, the structure of the fabric changes on rotation by 180°, which means they are asymmetric. However, there are instances where the nap direction of the knitted fabric does not matter. In the case of Jersey knit - having small loops, and smooth fabric texture permits an acceptable appearance in either direction.

Fabrics with surface fibres such as velvet are asymmetric. When mills prepare rolled piece goods, the "down direction” is usually toward the open end of the roll. And it is the same direction that the open ends of the fibres naturally point. Since velvet is made in rolled piece good form, it means that it has a distinct unidirectional nap, which implies it is asymmetric.

Related: What is Splicing in fabric spreading?

Spreading mode of the fabrics

The way in which fabric plies are spread for cutting is called determination of the spreading mode. While spreading the fabric it is important to consider the direction of the fabric nap. There are two ways in which a fabric can be spread depending on its type (symmetry, asymmetry)-Nap one way - As the name suggests, the nap is in the same direction implying that this spreading mode is for asymmetric and unidirectional fabrics. (Refer to example 1)

Nap either way- As the name suggests, the nap can be in any direction which means that this type of spreading mode is ideal for symmetric fabrics that do not change their appearance despite 180° rotation in the same plane. (Refer to example 3)

Now, the fabric face (while placing different layers on top of each other) may be positioned in two ways-

1) Face one way (F/O/W) - Which means, all plies facing in the same direction (either upward or downward)

2)Face-to-face (F/F) - This means, the face side of one layer is placed against the face side of another fabric layer.

Overall, we can now say that for any fabric there are the following possibilities in which they can be spread-

- Nap one way, face one way (NOW, F/O/W)

- Nap either way, face to face (NEW, F/F)

- Nap one way, face to face (NOW, F/F)

- Nap either way, face one way (NEW, F/O/W)

1. Nap one way, face one way (NOW, FOW)

It is the most common spreading method. As the name suggests, the nap is in one direction which means, it is a good alternative for an asymmetric fabric. Since the face side shall be in one specific direction, symmetric fabrics can be cut as well.

Manual spreading- The fabric roll is kept on a stationary roller stand and the fabric end is pulled by two spreading operators unwinding fabric from the freely rotating roll. Here fabric roll remains stationary. Visualize this scenario by looking at the illustration below-

Machine spreading- The loose end of the fabric is held by the catcher and the machine carries the rolls along the table length thus unwinding and spreading the fabric in the process. Every layer has to start from the same end thus spreading machine has to come back to the starting position without spreading the fabric. This return movement of the spreading machine is called “deadheading”. Check out the illustration below-

2. Nap either way, face to face (NEW, F/F)

It is the quickest spreading method when done using a spreading machine. However, it is difficult to accomplish manually. Remember, when deciding what type of fabric can be spread for the given spreading mode, one must consider the nap direction as well as the face of the fabric . Therefore, if you observe, the nap of the fabric will not change for both symmetric and asymmetric fabric.(Imagine the elephant printed fabric, you will realize that the foot of the mammal shall be towards the floor if it is spread in this spreading mode)

The machine carries the fabric roll while the end is being held in place by the catcher. The end of the fabric layer is not cut, it is folded and held by another catcher while the fabric is being laid by the machine during its return movement as well. Refer to the illustration below-

3. Nap one way, face to face (NOW, F/F)

Nap one-way, F/F is the most time-consuming method of spreading. Since the two similar faces of the fabric shall be placed against each other, it must be symmetric so that the look of the fabric does not change on 180° rotation.

The loose end of the fabric is held by the catcher and the machine carries the rolls along the table length while unwinding and spreading the fabric in the process. The fabric is cut at the end of the layer and the turntable rotates the fabric roll by 180 degrees. Meanwhile, the roll returns to the starting position without spreading (i.e. deadheading). The roll again spreads the second layer of the fabric face to face, and the process repeats.

To understand better, refer to the figure below which shows how the fabric shall be spread-

The figure below demonstrates how a piece of the pattern, when traced and cut out of this type of spreading mode shall look like-

4. Nap either way, face one way (NEW, F/O/W)

The loose end of the fabric is held by the catcher and the machine carries the rolls along the desired table length while unwinding and spreading the fabric in a process similar to the previous method. The fabric is cut at the end of the layer and the turntable rotates the fabric roll by 180 degrees. Meanwhile, the roll returns to the starting position spreading the fabric. The fabric is cut, roll rotates again, and then spreads the second layer of the fabric, and the process repeats. This type of spreading mode is ideal for symmetric fabrics. By doing so, despite the face of the fabric is spread in one direction, and the nap direction changes with each spread, the appearance of the fabric will not change. To understand this, look at the illustration below-

Imagine a piece of bodice pattern traced on top of each of the cases illustrated above. When cut out, for symmetric fabric, two parts shall come out identical. Meanwhile, for asymmetric fabric, one piece shall come out fine while the other will be tops turvy!

Conclusion:

To sum it up, refer to the table below-Related post: Cutting room terminologies

References

- The Technology of Clothing Manufacture by Harold Carr and Barbara Latham (Textbook)

- Garment Manufacturing Technology 1st edition edited by Rajkishore Nayak Rajiv Padhye (Textbook)

- Textiles (11th Edition) By Sara J. Kadolph (Textbook)

- Concepts of garment and fabric symmetry (Article)

Published: 11 November 2020

Updated:5 November 2023

About the Author:

Aayushi Kumar, an NIFT, Kolkata graduate, and Co-founder of Ednam Solutions Pvt Ltd is working in the field of female healthcare and hygiene, making smart garment.

Her interests include sustainable fashion, functional garments and luxury brand management.